-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Machine Considering Buying a King 1236ML Looking for Opinions

- Thread starter Jason Silliker

- Start date

Machine

Jason Silliker

Member

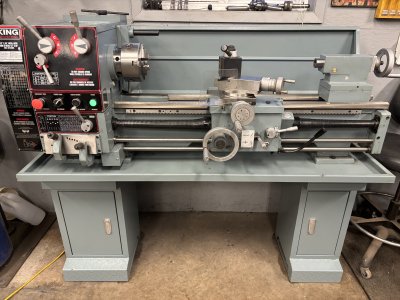

Took a little bit of time cleaned it up to see what I have. Really clean with no real rust. So glad the first one didn’t work out. This one seems to be in a lot better shape. Still have to clean up a little bit of the tools.

Don’t shoot me I sat it on the blocking and some shims just to get an idea for the height. Cabinets slide under nice just haven’t put the other one there yet and even though I’m not very tall it’s not a better height and lines up great with the window. Plan on adding a 3 inch piece to the back with a bunch of holes punch to fit the Morse tapers, seen a couple of other guys do it I liked how it looks. I made up this jack adaptor a few months ago works great for lifting small buildings and moving the stuff around lol.

Don’t shoot me I sat it on the blocking and some shims just to get an idea for the height. Cabinets slide under nice just haven’t put the other one there yet and even though I’m not very tall it’s not a better height and lines up great with the window. Plan on adding a 3 inch piece to the back with a bunch of holes punch to fit the Morse tapers, seen a couple of other guys do it I liked how it looks. I made up this jack adaptor a few months ago works great for lifting small buildings and moving the stuff around lol.

Attachments

Proxule

Ultra Member

Img 128, what the heck is that freckles or dimples or shiny shit on your ways?

Also, are you amused as I am/was at the non removable gap bed ways?

The gear rack / pinion rack has a split for it, as you can see in img 128, But the bed it self is not. Evertte's lathe does indeed split but his is considerably older!

Also, are you amused as I am/was at the non removable gap bed ways?

The gear rack / pinion rack has a split for it, as you can see in img 128, But the bed it self is not. Evertte's lathe does indeed split but his is considerably older!

Jason Silliker

Member

Bad pic, the shiny shit is oil after they were cleaned lol. Yeah even the new manual lists a bed gap but it’s non-existent.Img 128, what the heck is that freckles or dimples or shiny shit on your ways?

Also, are you amused as I am/was at the non removable gap bed ways?

The gear rack / pinion rack has a split for it, as you can see in img 128, But the bed it self is not. Evertte's lathe does indeed split but his is considerably older!

Yeah even the new manual lists a bed gap but it’s non-existent.

No big deal.

My lathe has a removable gap, but I wish it didn't. I've never removed it and absolutely never will.

Some guys say they never had a problem, and some say they lost alignment and were unable to fix it. I refuse to take the chance.

Jason Silliker

Member

Yeah I wouldn't use it either.No big deal.

My lathe has a removable gap, but I wish it didn't. I've never removed it and absolutely never will.

Some guys say they never had a problem, and some say they lost alignment and were unable to fix it. I refuse to take the chance.

1018Machine

Well-Known Member

Geez the thing looks practically brand new! Nice score!

I have one as well and for the most part it's a good machine. you learn it's deficiencies quick and with some tweaks it can be a decent machine.

I have one as well and for the most part it's a good machine. you learn it's deficiencies quick and with some tweaks it can be a decent machine.

Jason Silliker

Member

I’m sure it’s biggest deficiency will be me lol but what experiences are you referring to? Looking to glean as much information as I can. Newbie here lolGeez the thing looks practically brand new! Nice score!

I have one as well and for the most part it's a good machine. you learn it's deficiencies quick and with some tweaks it can be a decent machine.

but what experiences are you referring to? Looking to glean as much information as I can.

I don't think it has any deficiencies. Deficiencies are just optional add-ons and modifications waiting to happen.

I am nothing if not consistent.

You first project should be a lathe height standard. Search the forum for that - lots of great ideas and discussion.

Don't buy a carbide tool set. Huge waste of money and a distraction from getting good tools you will actually use. I am a big fan of starting with HSS!

1018Machine

Well-Known Member

I guess I shouldn't say deficiencies but like all lathe products coming in from overseas geared for the hobbyist they are made to that price specification so with that overall quality of fit and finish suffer, things like the gibs not being ground to a very good finish and gearing selection being somewhat limited. Holding tight tolerances is a chore with these machines but can be done with lots of patience. Overall fit and finish is yet to be desired but again you get what you pay for. I suppose for someone just getting into it these things aren't so much of a concern but once you have a few years under your belt you'll understand.I’m sure it’s biggest deficiency will be me lol but what experiences are you referring to? Looking to glean as much information as I can. Newbie here lol

I do agree with Susquatch on the tooling though, start with HSS and learn to grind your own, that will aid in shortening your learning curve to understand how different alloys react to things like rake angle and relief. Carbide is good but I'd save that for down the road once you understand those things as not any carbide tooling will be right for all situations, especially negative rake carbide as these machines simply aren't robust enough for them.

Have fun though, this is a very rewarding hobby.

especially negative rake carbide as these machines simply aren't robust enough for them.

I don't think that's necessarily true. I've helped 2 other guys with a Busy Bee 12" and a King 12", and they both handled negative rake just fine. Perhaps there are other 12" lathes that are not so rigid though. That's something that must be evaluated by each user.

Megar arc 5040dd

Super User

Busy be makes 2 different 12" lathes one is the 12x36 gear head lathe looks to be quite ridged the other is 12x28 and is a variable speed bench top lathe. I assume the bench top lathe would be less ridged as it is lighter. I believe King Canada only has the gear head 12x36. This is all just information I have come across in my own search for a lathe I haven't actually seen any of these in person to say for sure.I don't think that's necessarily true. I've helped 2 other guys with a Busy Bee 12" and a King 12", and they both handled negative rake just fine. Perhaps there are other 12" lathes that are not so rigid though. That's something that must be evaluated by each user.

Jason Silliker

Member

I believe you're correct. This one seems stout but time will tell.Busy be makes 2 different 12" lathes one is the 12x36 gear head lathe looks to be quite ridged the other is 12x28 and is a variable speed bench top lathe. I assume the bench top lathe would be less ridged as it is lighter. I believe King Canada only has the gear head 12x36. This is all just information I have come across in my own search for a lathe I haven't actually seen any of these in person to say for sure.

1018Machine

Well-Known Member

You might get away with light cuts but even the seller here where I am (which deals with much larger machinery than this) warns against it.I don't think that's necessarily true. I've helped 2 other guys with a Busy Bee 12" and a King 12", and they both handled negative rake just fine. Perhaps there are other 12" lathes that are not so rigid though. That's something that must be evaluated by each user.

I believe you're correct. This one seems stout but time will tell.

I guess it depends on whether or not it's a different lathe a shorter version of the otherwise identical lathe might be more rigid than the longer lathe. Also depends on whether one includes the weight of the stand and the other doesn't. Regardless, I'd bet a 12" lathe would probably be plenty rigid enough for hobby use and certainly more rigid than the equivalent smaller lathe.

You might get away with light cuts but even the seller here where I am (which deals with much larger machinery than this) warns against it.

If the seller has larger machines, then he will undoubtedly be biased (and probably trying to upsell bigger machines too). Of course bigger and heavier is more rigid. Surprise surprise. But that doesn't mean that a 12" won't still do it with relative ease. In the context of Hobby use, a 12" lathe is still a big lathe. With a decent tool holder and a proper setup, no problem at all using negative rake tools. Is a 14 or 16 better? Absolutely! But even if you have a 16", 20 will be better still. Sooner or later you have to shit or get off the pot. A 12" lathe is a VERY NICE Lathe. With a proper setup, it will easily handle negative rake tools. I'm not budging from that opinion.

About 20% of our members have a 12" lathe. That's a pretty high number. Why not ask them directly! Darn good chance that most of them have tried it and will be able to say if it works or not. Count me as one who has seen it with his own two eyes (I had 2 at the time but I'm a one eyed man ever since my stroke).

Your machine jack Jason, super nice and very handy.Took a little bit of time cleaned it up to see what I have. Really clean with no real rust. So glad the first one didn’t work out. This one seems to be in a lot better shape. Still have to clean up a little bit of the tools.

Don’t shoot me I sat it on the blocking and some shims just to get an idea for the height. Cabinets slide under nice just haven’t put the other one there yet and even though I’m not very tall it’s not a better height and lines up great with the window. Plan on adding a 3 inch piece to the back with a bunch of holes punch to fit the Morse tapers, seen a couple of other guys do it I liked how it looks. I made up this jack adaptor a few months ago works great for lifting small buildings and moving the stuff around lol.