Another project suddenly and officially on hold.

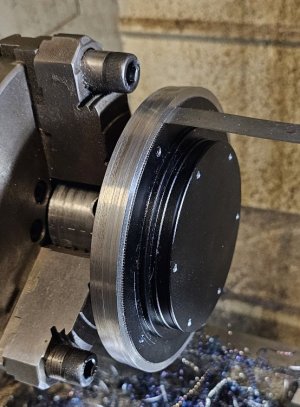

I mounted my 4 jaw and then centered the degree plate in the collet. I centered it to a half thou. Why so precise? Well.... why not? Of note, 4 ears were more than adequate. The collet grips extremely well - maybe too well......

View attachment 54197

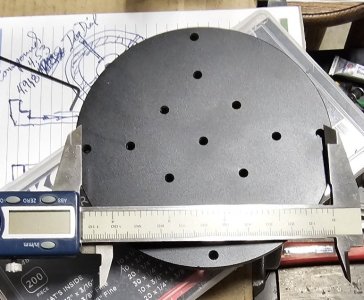

Then I cleaned up all the steel swarf to switch to aluminium. And then started trepanning the plate.

View attachment 54198

You can also see my mistake above. The chip on my compound is too big. Rookie mistake. Slow and steady is better. I was too anxious to start and finish a big project before

@DavidR8 could knock off another two dozen. Just as i broke through the plate, it grabbed like a crocodile and just like that, the plate was ruined. Fk.

I'll order another plate tomorrow. Fortunately, all my other work is just fine so I don't need to start over. Just drill and tap for 4 set screws, and trepan a new disk.

Insert big sigh here......