Megar arc 5040dd

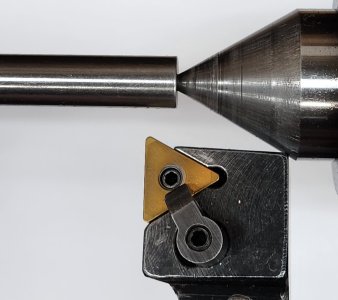

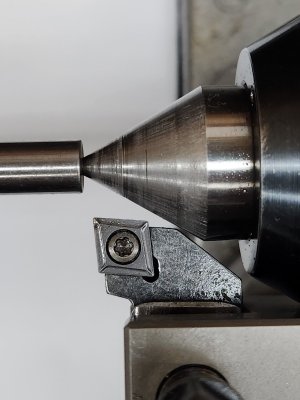

Super User

I am wondering what the difference is, other than the shape itself, between the different shapes of lathe inserts? For examaple is there an advantage or disadvantage to any of the following shape of inserts? CCMT, DCMT, TCMT, WCGT. Please correct me if I have the abbreviations/codes wrong I am asking about 80* rhombic, 55* rhombic, triangle, and trigon. I have been using HSS 99% of the time over the last 15 years but would like to pick up some more insert tools. Both for convenience as well as the times where the material just messes up the HSS. I have a couple tools that use CCMT that I have had mixed results with. I believe this could just be the busy bee tools inserts I bought about 15 years ago that I only just used the last one I had the other day. I am going to pick up different nose radius to try as well as some sharper edged ones for aluminum. That got me thinking that I don't seem to notice people in youtube using CCMT as much as TCMT or DCMT. I was wondering if there is a reason and if one shape it better than another for generalt use.

A bit more information on my specific use case. My lathe is a babit bearing 10 inch atlas. Most of what I turn is mystery steel as well as some 1018 and aluminum. I ran into a situation the other day when turning down a craftsman socket into thin wall cheaper than snap on socket. HSS went dull really fast and gave a poor finish but carbide worked really nice and gave a nice finish. I figured since I am ordering inserts if there were other types that work better I would give them a try.

A bit more information on my specific use case. My lathe is a babit bearing 10 inch atlas. Most of what I turn is mystery steel as well as some 1018 and aluminum. I ran into a situation the other day when turning down a craftsman socket into thin wall cheaper than snap on socket. HSS went dull really fast and gave a poor finish but carbide worked really nice and gave a nice finish. I figured since I am ordering inserts if there were other types that work better I would give them a try.