Depending on the setup, wedges are preferred for chuck/arbor separation. I know, more $$. Tapping around on the periphery is also done but potentially at the risk of bending the arbor or peeing the bearings. So that leaves heat or press? Chucks also vary in how they are retained. Assuming you don't have a clamping collar style. Maybe others can chime in if the end of arbor can be knocked out with a rod inside jaws, or is the chuck body always solid in there.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Beginner question: Runout with a new Chinese drill chuck

- Thread starter VicHobbyGuy

- Start date

or is the chuck body always solid in there.

I have two BB chucks where the arbor hole passes right thru (i.e. not blind). I can remove the arbors with a punch.

Jacobs require the wedges.

Last edited:

VicHobbyGuy

Ultra Member

. Maybe others can chime in if the end of arbor can be knocked out with a rod inside jaws, or is the chuck body always solid in there.

I feel foolish - I presumed the chuck had a solid bottom, but it doesn't. Thanks, guys!I have two BB chucks where the arbor hole passes right thru (i.e. not blind). I can remove arbors with a punch.

That was easy!

So the next step is to put something in the chuck jaws, grab that in the lathe chuck, and hand rotate it and put the DTI inside the chuck taper where the arbor goes?

I feel foolish - I presumed the chuck had a solid bottom, but it doesn't. Thanks, guys!

View attachment 21841

That was easy!

So the next step is to put something in the chuck jaws, grab that in the lathe chuck, and hand rotate it and put the DTI inside the chuck taper where the arbor goes?

So now you can put the arbor between centers and see if that tells you anything...... Maybe the MT taper isn't concentric with the chuck taper or the arbor is bent.

Last edited:

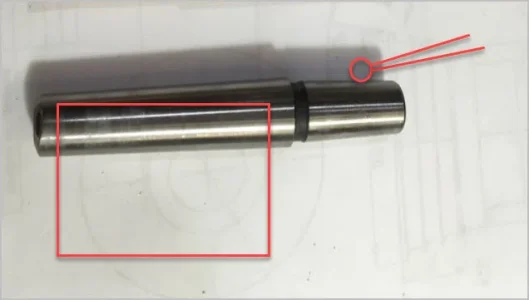

Test-1: Position the taper segment in a Vee block. You probably need to backstop the end to prevent fore-aft movement. Anyways now you can position a DTI ball on the chuck taper & see what's going on runout wise, slowly rotating. If deviated mark the arbor with Sharpie & see if that correlates to wear chuck is running out.

Test-2: (no picture) grip the most accurate dowel pin you have in chuck jaws. Now lay that extended pin in Vee block groove. Measure the seat of chuck taper as you rotate. (might take a few extra hands to put a bit of contact pressure on the Vee, but this method eliminates anything spindle related.

Test-2: (no picture) grip the most accurate dowel pin you have in chuck jaws. Now lay that extended pin in Vee block groove. Measure the seat of chuck taper as you rotate. (might take a few extra hands to put a bit of contact pressure on the Vee, but this method eliminates anything spindle related.

Attachments

VicHobbyGuy

Ultra Member

Thanks. Those are on the ToDo list.

VicHobbyGuy

Ultra Member

I think this one is solved.

I tested the runout on the chuck body and socket, and the arbor separately and they were both 'OK' 0.07mm (about 0.003")or less runout.

Mated them together and the 0.35mm runout was back, but wait....that didn't feel tight.....No matter how much I 'wrung' them together I could still feel looseness.

Just to confirm that I wasn't hallucinating, I put some Prussian Blue on the arbor and 'mated' it with the chuck socket.

It's not easy to see but the Blue at the wide end of the arbor isn't 'scrubbed off', and that's where it felt loose, too.

So while I was pondering this, and staring at the chuck and arbor I noticed: Chuck B16, Arbor MT2-JT33

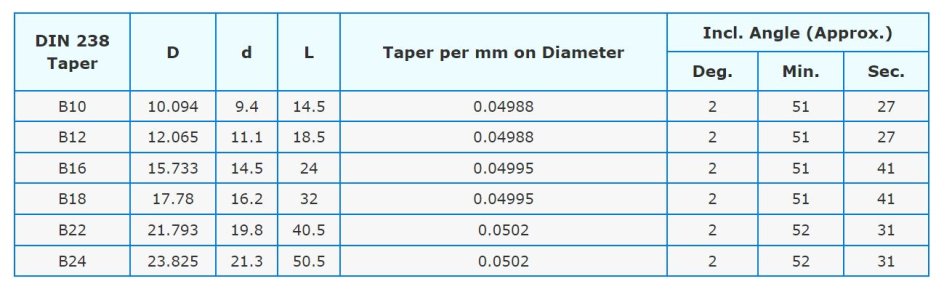

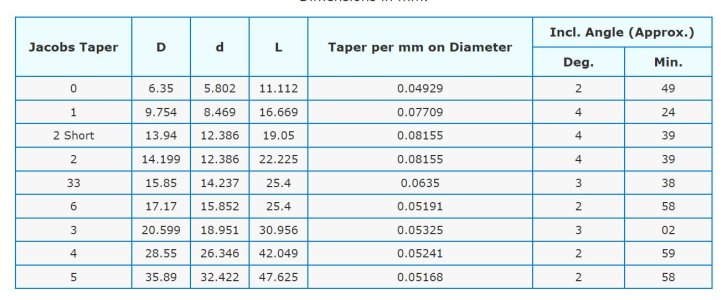

I hadn't realized that B16 is actually a taper (it's the same as Morse 2); I'd thought that it was a chuck size designation of some sort. Definitely different than Jacobs JT33.

So arbor and chuck don't mate properly.

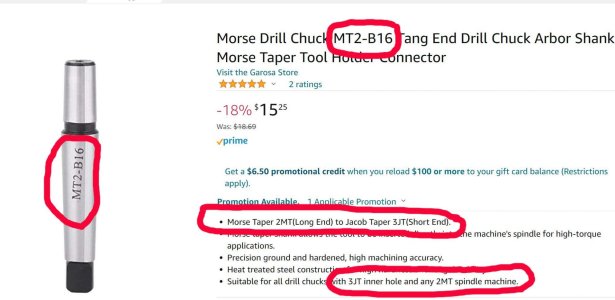

It seems to me that a new arbor - MT2-B16 should fix the problem. Does this make sense?

I tested the runout on the chuck body and socket, and the arbor separately and they were both 'OK' 0.07mm (about 0.003")or less runout.

Mated them together and the 0.35mm runout was back, but wait....that didn't feel tight.....No matter how much I 'wrung' them together I could still feel looseness.

Just to confirm that I wasn't hallucinating, I put some Prussian Blue on the arbor and 'mated' it with the chuck socket.

It's not easy to see but the Blue at the wide end of the arbor isn't 'scrubbed off', and that's where it felt loose, too.

So while I was pondering this, and staring at the chuck and arbor I noticed: Chuck B16, Arbor MT2-JT33

I hadn't realized that B16 is actually a taper (it's the same as Morse 2); I'd thought that it was a chuck size designation of some sort. Definitely different than Jacobs JT33.

So arbor and chuck don't mate properly.

It seems to me that a new arbor - MT2-B16 should fix the problem. Does this make sense?

VicHobbyGuy

Ultra Member

VicHobbyGuy

Ultra Member

I think you are on the right track. This is exactly what I was referring to about the chuck cocking up on the arbor (mismatched taper). It will find a home & feel tight, but its not co-axial = runout

It might be a case of sloppy or erroneous product labelling. If you have a means of mounting the arbor you could even validate the published angle.

Assuming the chuck is correct it should be a matter of finding the corresponding arbor.

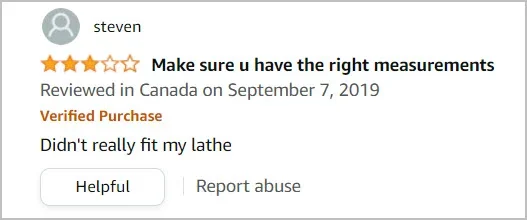

I noticed this one had a similar review. Maybe coincidental, hmmmm...

It might be a case of sloppy or erroneous product labelling. If you have a means of mounting the arbor you could even validate the published angle.

Assuming the chuck is correct it should be a matter of finding the corresponding arbor.

I noticed this one had a similar review. Maybe coincidental, hmmmm...

JRL MT2 to B16 Drill Chuck Connecting Shaft Rod Morse Taper Shank Arbor Adapter with Tang End Morse Taper 2 B16 Arbor Industrial : Amazon.ca: Industrial & Scientific

JRL MT2 to B16 Drill Chuck Connecting Shaft Rod Morse Taper Shank Arbor Adapter with Tang End Morse Taper 2 B16 Arbor Industrial : Amazon.ca: Industrial & Scientific

www.amazon.ca

Attachments

VicHobbyGuy

Ultra Member

And, since B16 is the same as the small end of MT2, I reversed the arbor and put the MT2 end into the B16 chuck socket - it mated securely and the chuck/arbor combo now had 0.07mm runout.

I think a new arbor definitely will fix this. Thanks for all the help you folks provided.

I think a new arbor definitely will fix this. Thanks for all the help you folks provided.

VicHobbyGuy

Ultra Member

Not installed, but the Banggood seller put the B16 taper chuck and the JT33 taper arbor in the same little box, so -trusting soul that I am - I just cleaned off the oil and mated them together. They 'seemed to fit' and I didn't think any further about it. I figured the B16 was the chuck capacity (5/8" ~ 16mm) and the JT33 marked on the arbor was the taper on both the arbor and chuck.Do I understand this correctly? Banggood shipped you a chuck with the wrong arbor installed?

It wasn't until you mentioned driving out the arbor through the open back of the chuck ("Gee, that was pretty easy, I thought...") that I started really paying attention to those tapers!

I guess it's nice to still be in the "live and learn" stage even at my advanced age??

VicHobbyGuy

Ultra Member

A quick follow-up to let you know what happened with the Banggood Customer 'Service'....

I complained a.k.a. 'Opened a ticket' to Banggood and provided description of the problem and some pics of the runout and the chuck. Immediate response (automatic via software as all the responses were....)."Please provide proof." "Pictures" "Please upload video to YouTube and provide a link".(You can't upload videos to banggood)

So I sent a couple more pictures and managed to ujpload a short video to Youtube.

Banggood: "Please provide more proof." "Pictures of original packaging and wrapping on parcel"

I replied with a message - packaging was gone, I'd provided enough proof, etc...

Banggood: "7 days with no response. Ticket CLOSED"

I wasn't surprised. All those purchases from China are a gamble. Generally if something just never arrives I get a refund. On quality issues, it's just a 'what did you expect?' sort of situation. I don't spend more than I can afford to lose without getting upset.

Banggood did allow my negative review to appear on the product page, so that's more than a lot of sites allow.

I complained a.k.a. 'Opened a ticket' to Banggood and provided description of the problem and some pics of the runout and the chuck. Immediate response (automatic via software as all the responses were....)."Please provide proof." "Pictures" "Please upload video to YouTube and provide a link".(You can't upload videos to banggood)

So I sent a couple more pictures and managed to ujpload a short video to Youtube.

Banggood: "Please provide more proof." "Pictures of original packaging and wrapping on parcel"

I replied with a message - packaging was gone, I'd provided enough proof, etc...

Banggood: "7 days with no response. Ticket CLOSED"

I wasn't surprised. All those purchases from China are a gamble. Generally if something just never arrives I get a refund. On quality issues, it's just a 'what did you expect?' sort of situation. I don't spend more than I can afford to lose without getting upset.

Banggood did allow my negative review to appear on the product page, so that's more than a lot of sites allow.

Well that kind of blows. They seemed more adamant about proving that the item originated from them - packaging, parcel particulars etc. - vs the quality issue. One would think if they had on record an item recently purchased & confirmation of shipment arrived & pictures looks like the item... then its 99.9% probably the item. Would be interesting if you just happened to have kept packaging would just proceed to the next item on trivia list just to wear you down & run out the clock. I've only had a few issues on AliExpress & it was painless refund, no issues at all. Maybe lucky so far.

VicHobbyGuy

Ultra Member

That's what I assumed is the StandardOperatingProcedure at Banggood Customer Service, and I read a bunch of expeeriences on the web that indicated I'm not the first person to experience this. So - heads up, readers!! If this would really really irritate you, don't shop on Banggood.Would be interesting if you just happened to have kept packaging would just proceed to the next item on trivia list just to wear you down & run out the clock.