-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Beginner machinist question??

- Thread starter Gunguy

- Start date

Brent H

Ultra Member

@ThirtyOneDriver - that is a nice looking face plate. Looks like you will need a mounting back plate that will fit it to your lathe

Edit: My bad - just checked the manual and you loosen the three bolts and re-attach the chuck or face plate straight to the spindle. Backing is integral with the spindle.

Edit: My bad - just checked the manual and you loosen the three bolts and re-attach the chuck or face plate straight to the spindle. Backing is integral with the spindle.

Last edited:

ThirtyOneDriver

Johnathan (John)

I feel like a child in my Dad's shop - "What's this do?"

Back plate? The one the chuck is bolted to?

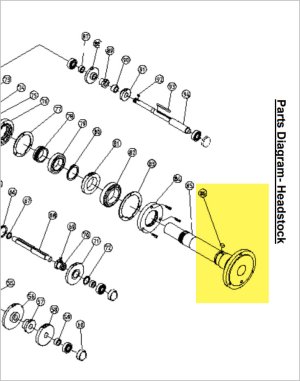

View attachment 19821

Side note: Brake clean destroys the paint on this lathe but not the milling machine... (see primer behind chuck)

That's not a back plate that's your spindle nose. Your chucks and face plate bolt to the spindle nose and have an alignment recess. Post a pic of the back side of your 4J and face plate.

Last edited:

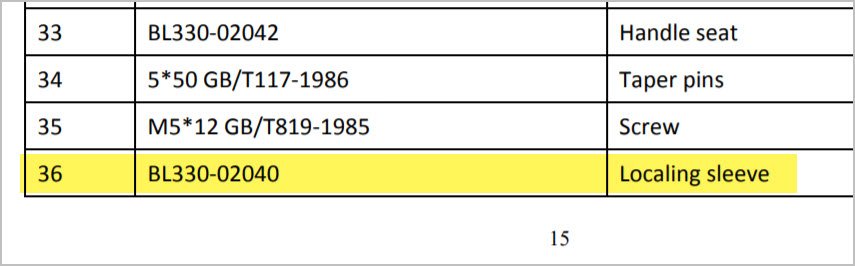

Well I beg to differ, but according to the manufacturer, it appears to be the 'Localing sleeve' LOL. Just kidding. I'm not familiar with the machine but I'd agree that spindle face seems like a good name to me.

Guessing the 3 screw configuration is just like the chuck. Yes, lets see the other side.

Guessing the 3 screw configuration is just like the chuck. Yes, lets see the other side.

Attachments

The best way for me to say this is as follows.

A chuck attaches to the lathe spindle with some kind of attaching interface. The interface can be integral to the chuck or they can be adapted to the spindle with a backplate. You can get chucks that fit your lathe directly or that need a backplate to adapt the chuck to the spindle.

What the heck is that in your chuck jaws? It looks like a morse taper dead center. It's too small to fit your spindle so it is prolly for your tailstock. In any event, if it's what it looks like, it should not be chucked in the head. It could get ruined that way. It should only be used in a female MT hole.

A chuck attaches to the lathe spindle with some kind of attaching interface. The interface can be integral to the chuck or they can be adapted to the spindle with a backplate. You can get chucks that fit your lathe directly or that need a backplate to adapt the chuck to the spindle.

What the heck is that in your chuck jaws? It looks like a morse taper dead center. It's too small to fit your spindle so it is prolly for your tailstock. In any event, if it's what it looks like, it should not be chucked in the head. It could get ruined that way. It should only be used in a female MT hole.

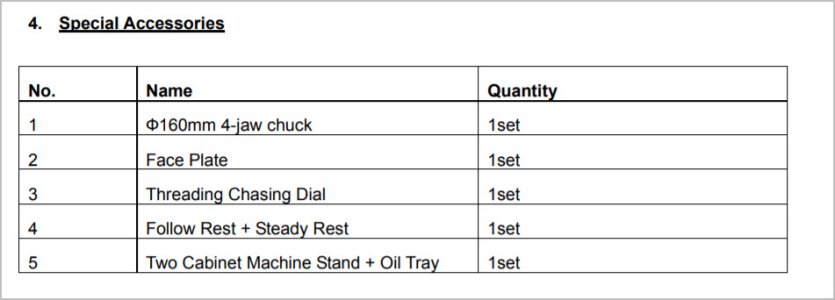

The big plate with slots in it is called a face plate. It's sort of like a rotating bed plate that large parts are attached to for turning.

Many lathes come with:

1. a scrolling 3 jaw chuck for parts that are already round.

2. a non-scrolling 4 jaw chuck for non round parts or precision centering of round parts.

3. A face plate for other kinds of parts that cannot be held in a 3 or 4 jaw chuck.

Many lathes come with:

1. a scrolling 3 jaw chuck for parts that are already round.

2. a non-scrolling 4 jaw chuck for non round parts or precision centering of round parts.

3. A face plate for other kinds of parts that cannot be held in a 3 or 4 jaw chuck.

@DHHok @PeterT - does a back plate look something like this?

View attachment 19818

This was included w/ the CX709

Are you in Cambridge?

I am thinking that a trip to your place while my bride visits her mom would be very useful to you. I could run through what you have with you and show you what it does. I'll prolly be going on Friday the 25th.

I'll be the guy who looks like he could be your dad......

ThirtyOneDriver

Johnathan (John)

I need supervision *hangs head*....

Yes, Cambridge, I'll make myself available for the 25th - I'll send you a message shortly @Susquatch.

Pictures of the lathe (took the center thingy out of the chuck jaws and put it where it belongs, in the tailstock).

Four-way chuck as mentioned and I think the spindle may have a M4 taper, possibly... I wouldn't trust my memory in this case.

Sidenote: EVERYTIME you guys are shaking your heads going "what the 'h'", I'm already laughing at myself because, well it's funny... I have some experience with some things, but machining (and everything related outside of welding/fabricating) is not one of them - someone once showed me how to turn on a lathe, no other familiarity, not something that Dad was into or anyone else that I got to be around or anything... I haven't been hurt yet, so I see the humor in it.

Yes, Cambridge, I'll make myself available for the 25th - I'll send you a message shortly @Susquatch.

Pictures of the lathe (took the center thingy out of the chuck jaws and put it where it belongs, in the tailstock).

Four-way chuck as mentioned and I think the spindle may have a M4 taper, possibly... I wouldn't trust my memory in this case.

Sidenote: EVERYTIME you guys are shaking your heads going "what the 'h'", I'm already laughing at myself because, well it's funny... I have some experience with some things, but machining (and everything related outside of welding/fabricating) is not one of them - someone once showed me how to turn on a lathe, no other familiarity, not something that Dad was into or anyone else that I got to be around or anything... I haven't been hurt yet, so I see the humor in it.

I need supervision *hangs head*....

Yes, Cambridge, I'll make myself available for the 25th - I'll send you a message shortly @Susquatch.

Pictures of the lathe (took the center thingy out of the chuck jaws and put it where it belongs, in the tailstock).

View attachment 19840 View attachment 19842

Four-way chuck as mentioned and I think the spindle may have a M4 taper, possibly... I wouldn't trust my memory in this case.

View attachment 19841 View attachment 19843

Sidenote: EVERYTIME you guys are shaking your heads going "what the 'h'", I'm already laughing at myself because, well it's funny... I have some experience with some things, but machining (and everything related outside of welding/fabricating) is not one of them - someone once showed me how to turn on a lathe, no other familiarity, not something that Dad was into or anyone else that I got to be around or anything... I haven't been hurt yet, so I see the humor in it.

No worries. I laugh at myself all the time. And I love it when I can be the source of laughter for others too.

I'll look for your PM, and look forward to the visit on the 25th.

justindavidow

(Justin)

I laugh at myself all the time. And I love it when I can be the source of laughter for others too.

This is the way!

Seriously; I cannot think of better life advice.

ThirtyOneDriver

Johnathan (John)

@YYCHM Craig! - good buddy! what type of grease? On hand I have wheel bearing grease (Lucas Oil, green, yucky) for packing wheel bearings; Tacky Red for packing racecar wheel bearings using a needle and syringe; lithium white grease (Lucas Oil) that I'd love to throw in the garbage can; standard tractor grease for the John Deere's grease fittings; the silver grease to put on your friend's truck door handles while they're pissing behind the shop... any of those work? Is any of it going to fly off and make a mess anywhere? (I work on racecars because you can eat off of them - goal is to keep my hands clean as much as possible.

@Tom Kitta - since it looks like the elders have spoken and I'm getting ready to buy grease, what oil am I buying for the CX709 lathe? Happen to know how much I should need? Same oil can be used for oiling points on the lathe and mill?

@Tom Kitta - since it looks like the elders have spoken and I'm getting ready to buy grease, what oil am I buying for the CX709 lathe? Happen to know how much I should need? Same oil can be used for oiling points on the lathe and mill?

@YYCHM Craig! - good buddy! what type of grease? On hand I have wheel bearing grease (Lucas Oil, green, yucky) for packing wheel bearings; Tacky Red for packing racecar wheel bearings using a needle and syringe; lithium white grease (Lucas Oil) that I'd love to throw in the garbage can; standard tractor grease for the John Deere's grease fittings; the silver grease to put on your friend's truck door handles while they're pissing behind the shop... any of those work? Is any of it going to fly off and make a mess anywhere? (I work on racecars because you can eat off of them - goal is to keep my hands clean as much as possible.

Any thing is better than nothing. Your manual states machine oil what ever that is? That lithium white grease (Lucas Oil) that I'd love to throw in the garbage can would suffice and ya it's going to sling.

DPittman

Ultra Member

I agree with @YYCHMAny thing is better than nothing. Your manual states machine oil what ever that is? That lithium white grease (Lucas Oil) that I'd love to throw in the garbage can would suffice and ya it's going to sling.

I'll add my two cents worth , of all the choices of grease you have on hand I think the last one I would use would be the lithium but it's uch better than nothing. I'd use the stickiest thickest stuff you have and it doesn't take much as the excess definitely get flung off anyhow. Id use any 80/90 weight gear oil in the gearbox......and with that said you will now have many different opinions being thrown at you telling us that we are wrong.

Last edited:

I agree with @YYCHM

I'll add my two cents worth , of all the choices of grease you have on hand I think the last one I would use would be the lithium but it's uch better than nothing. I'd use the stickies thickest stuff you have and it doesn't take much as the excess definitely get flung off anyhow. Id use any 80/90 weight gear oil in the gearbox......and with that said you will now have many different opinions being thrown at you telling us that we are wrong.

Ya, that about sums it up. No matter what you choose there will be arguments about it.

But @YYCHM is right, anything is better than nothing.

I like "Red and Tacky" (it's a brand of grease) for places where slinging is a potential problem. It is stickier than most other grease.

When you first apply any grease on the gears, put or hold a cardboard gaurd between the greased location and the belt system. Keep the grease off of that belt and it's pulleys. You won't be 100% effective but you do need to try.

I also agree on the oil with one caveat. As an automotive guy, my advice is to always follow the manufacturers recommendations for the warranty period. You never want to give them an excuse to turn down a warranty claim.

Just in case there is a misunderstanding or a terminology gap, you need:

Cutting oil for ferrous metals

Cutting oil for aluminium

Light Oil for small parts

Heavy oil for bigger parts

Gear oil for gear cases

Way oil for the ways

Grease for the gears

Honing oil for sharpening

You also need Corrosion protection for tools and surfaces.

And I'm prolly forgetting something cuz I have a few dozen other oils and greases I use around the farm.

ThirtyOneDriver

Johnathan (John)

Interesting... "Red Tacky" it is for the gears - good reminder about the belts - no warranty (the CX709"x" that came heavily discounted w/ no BB support) - I have an excess of 70w90 and regularly have "lightly used" (20 minutes in a rearend) 70w90 that I'm disposing of (I've been using this as a cutting lubricant w/ a little spray bottle).

Interesting... "Red Tacky" it is for the gears - good reminder about the belts - no warranty (the CX709"x" that came heavily discounted w/ no BB support) - I have an excess of 70w90 and regularly have "lightly used" (20 minutes in a rearend) 70w90 that I'm disposing of (I've been using this as a cutting lubricant w/ a little spray bottle).

Well..... I dunno about using an actual lubricating oil as a cutting fluid..... It might work but I really don't think it will work very well. For that matter, lots of stuff will work, but not very well. Machinists have spent a lifetime developing good cutting fluids. There are hundreds on the market. I'd bet a week's worth of coffee or a case of beer that NONE OF THEM are gear oil......

I use Vipers Venom because it is highly popular and recommended by many machinery and tooling companies. It is very popular with the smithing industry. I used to buy it in bulk from "The Reamer Guy" in BC who got it directly from Viper Machining. But you can get it on Amazon now.

I like it because it works great on all ferrous metals and is quite sticky so it will follow the cutting point and last several passes.

Some others use a spray bottle on the lathe, some use a brush, but I use a dropper bottle. I have used a pump with continuous flow but even with a tray, it's too messy for my liking.

Anyway, my advice is to lose the gear oil for cutting and buy some dedicated cutting oil.

Last edited:

Dabbler

ersatz engineer

Besides cutting oil is cheap cheap...Anyway, my advice is to lose the gear oil for cutting and buy some dedicated cutting oil.