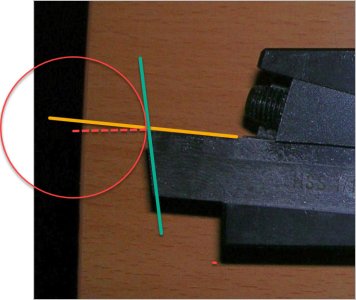

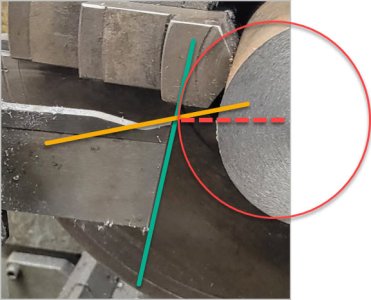

Mine has no height adjuster. Just held be the wedge dovetail. The height adjuster should see none of the cutting forces, really, the wedge does fine.

on a small lathe yes, but even my Emco can part off with power feed at some pretty high feed rates with no issues, with a toolpost and compound. Keeping everything choked up as close as possible helps a lot. On bigger machines this is less important. In my parting video earlier, the blade was out at least 1.75, probably 1.875 or so. it is a 1.125" high blade though. But i never did anything else. No oil, etc.

Just a 4" drill. I actually reamed it too, to avoid stress risers, probably totally unnecessary, but why not. It cost an extra beer.

its scaptonium, If you come accros some, send it to me for proper disiposal

Surface treatment? I own a cummins. Used Cummins engine oil is like holy water for ametuer machinists.

Like sacrificing a virgin goat or something...

But really, it has stuff in it that sticks to really hot metal. Heated it up to dull cherry and dumped it in the used oil, wiped off with rag, admired for several beers, then tested.

Thats a bucket pin from a back-hoe. A dirty cat hoe. I made new pins in an attempt to tighten the old gal up, but alas, she'd been around the block a few times. Made it better though, and I got 50lbs of metal to play with.