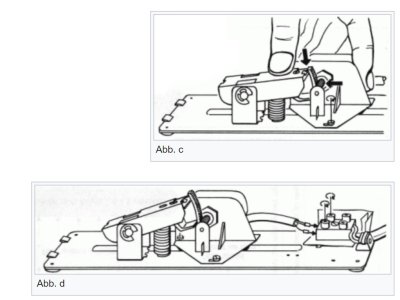

Should still support the other end of the pinion shaft. Don't use the pot bushing to handle any load."sliding (vertical) rack in a channel and pinion on the pot shaft"

My plan B, above.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Any solutions to my problem?

- Thread starter DPittman

- Start date

DPittman

Ultra Member

Yes that was one of my fatal mistakesShould still support the other end of the pinion shaft. Don't use the pot bushing to handle any load.

It's like software. Sometime you have crumple up the page and toss it in the trash and start fresh.

DPittman

Ultra Member

Thank goodness I will never have to worry about having that scenario also.It's like software. Sometime you have crumple up the page and toss it in the trash and start fresh.

The word "software" should be replaced with "Microsoft Windows"

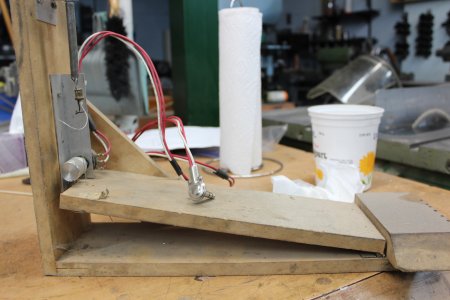

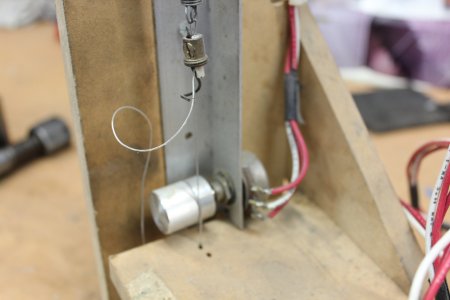

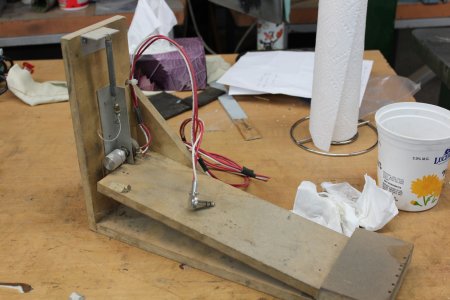

I am almost embarrassed to show you this, but it has worked so well for many hours over many years that I guess it is worth having a look at. The cord from the spring, around the pot knob to the foot pedal is a very fine nylon covered? multi-strand cable, but lots of other things should work. I cobbled it together for a job winding magnetic coils with the intention of improving it if the whole winder worked, but it worked so well I never had a reason to change it. Occasionally the cable may slip a bit and off is not off, but you just draw the spring down to take the tension off, reset the pot and good to go.

Attachments

There's nothing wrong with your solution and the mechanical characteristics of the 1/4" shaft pot are what make it work so well! Change that to an 1/8" shaft and it's not really meant for that sort of load. But again, all it takes is a bearing support on the other end.I am almost embarrassed to show you this, but it has worked so well for many hours over many years that I guess it is worth having a look at. The cord from the spring, around the pot knob to the foot pedal is a very fine nylon covered? multi-strand cable, but lots of other things should work. I cobbled it together for a job winding magnetic coils with the intention of improving it if the whole winder worked, but it worked so well I never had a reason to change it. Occasionally the cable may slip a bit and off is not off, but you just draw the spring down to take the tension off, reset the pot and good to go.

DPittman

Ultra Member

Ha ha I love it!I am almost embarrassed to show you this, but it has worked so well for many hours over many years that I guess it is worth having a look at. The cord from the spring, around the pot knob to the foot pedal is a very fine nylon covered? multi-strand cable, but lots of other things should work. I cobbled it together for a job winding magnetic coils with the intention of improving it if the whole winder worked, but it worked so well I never had a reason to change it. Occasionally the cable may slip a bit and off is not off, but you just draw the spring down to take the tension off, reset the pot and good to go.

I'm giving my #3 version attempt at this thing mostly because I'm learning alot and need practice at some things. I'm going to attempt to cut my own nylon gears using a new dividing head and I'll likely screw up using that once or twice also. Despite my frustrations, I am kind of enjoying myself

The 1/4 shaft is better, no doubt, but notice that the cable is in a straight line, and the tension above and below is balanced when not in motion, adding no bending moment to the shaft. When travelling, the difference between the top and bottom segments of the cable are only the small torque of the pot. Pots are cheap, can you substitute a more robust pot if you are worried?There's nothing wrong with your solution and the mechanical characteristics of the 1/4" shaft pot are what make it work so well! Change that to an 1/8" shaft and it's not really meant for that sort of load. But again, all it takes is a bearing support on the other end.

mickeyf

Super User

occasionally the cable may slip a bit and off is not off,

That could probably be dealt with by anchoring the cable to the knob at one point. I like this. Yes, "Often simple is best".