Re: test of heat shrink connectors with solder:

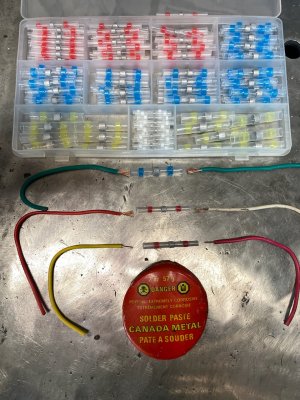

I’ve received and tried the (inexpensive from Amazon) electrical wire connectors that shrink + on have adhesive +solder all in one.

Here’s the good, the bad, and the ugly of my test -

I connected: 14 gauge strand wire both with and without solder flux; 20 gauge strand wire; and 20 gauge solid wire. I used a heat gun designed to start charcoal as a heat source- likely a bit too agressive but it’s what i have and it’s less aggressive & more controllable than an open flame.

Note 1- It was hard to melt the solder without damaging the adjacent wire insulation.

Note 2 - maybe a less aggressive heat source would have been better, i monitored the temperature and tried to keep it below 200 F.

Results:

The good- the 14 gauge with the flux looks great and couldn’t be pulled apart. Also good was the connection with the 20 gauage wire.

The bad - the other 14 gauge connection without flux pulled apart easily (i think the failure had nothing to do with the flux)

The ugly - the 20 gauge solid wire pulled apart easily.

Bottom line:

- Maybe more practice and a better heat source would have given better results;

- commercial grade connectors likely better than sourcing from Amazon

- could have twisted the wires but i followed the instructions;

- didn’t think it is a worthwhile time saver considering how seldom I do this (vs solder the connection and then using a good heat shrink that has adhesive);

- failure rate was too high;

- this procedure is too sensitive;

- glad I didn’t spend more than $20 bucks to lean these connectors are not for me!!!

I’ve received and tried the (inexpensive from Amazon) electrical wire connectors that shrink + on have adhesive +solder all in one.

Here’s the good, the bad, and the ugly of my test -

I connected: 14 gauge strand wire both with and without solder flux; 20 gauge strand wire; and 20 gauge solid wire. I used a heat gun designed to start charcoal as a heat source- likely a bit too agressive but it’s what i have and it’s less aggressive & more controllable than an open flame.

Note 1- It was hard to melt the solder without damaging the adjacent wire insulation.

Note 2 - maybe a less aggressive heat source would have been better, i monitored the temperature and tried to keep it below 200 F.

Results:

The good- the 14 gauge with the flux looks great and couldn’t be pulled apart. Also good was the connection with the 20 gauage wire.

The bad - the other 14 gauge connection without flux pulled apart easily (i think the failure had nothing to do with the flux)

The ugly - the 20 gauge solid wire pulled apart easily.

Bottom line:

- Maybe more practice and a better heat source would have given better results;

- commercial grade connectors likely better than sourcing from Amazon

- could have twisted the wires but i followed the instructions;

- didn’t think it is a worthwhile time saver considering how seldom I do this (vs solder the connection and then using a good heat shrink that has adhesive);

- failure rate was too high;

- this procedure is too sensitive;

- glad I didn’t spend more than $20 bucks to lean these connectors are not for me!!!