Tom Kitta

Ultra Member

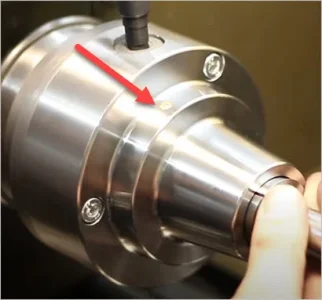

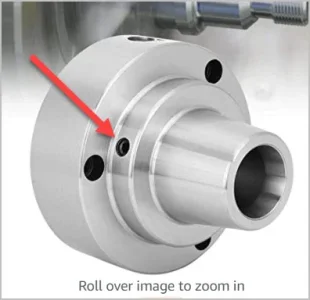

So since others were buying chucks I just got a new one - 5C.

Reviews are good:

Amazon

I paid 160 with tax and prime delivery.

As soon as I paid price jumped to... 301 plus tax... got to love Amazon surge algorithm. Cheapest on ali are about 225 plus any taxes in Canada if any.

I was going to hope amazon does not do this and someone can get one at 160. I think that was a good deal.

Reviews are good:

Amazon

5C Tools Clamp Chuck Lathe Parts, 3911-125 Hardware Accessory Industrial Supplies High Accurancy, with a Chuck and Drill Key, for Lathes, Grinders : Amazon.ca: Tools & Home Improvement

5C Tools Clamp Chuck Lathe Parts, 3911-125 Hardware Accessory Industrial Supplies High Accurancy, with a Chuck and Drill Key, for Lathes, Grinders : Amazon.ca: Tools & Home Improvement

www.amazon.ca

I paid 160 with tax and prime delivery.

As soon as I paid price jumped to... 301 plus tax... got to love Amazon surge algorithm. Cheapest on ali are about 225 plus any taxes in Canada if any.

I was going to hope amazon does not do this and someone can get one at 160. I think that was a good deal.