Wes D.

Member

Hello,

First off, I have no idea what I'm doing

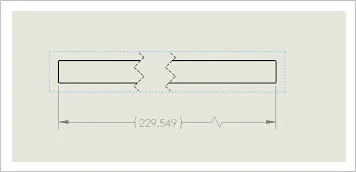

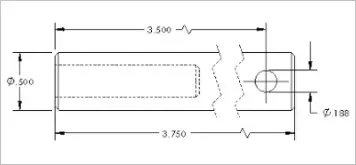

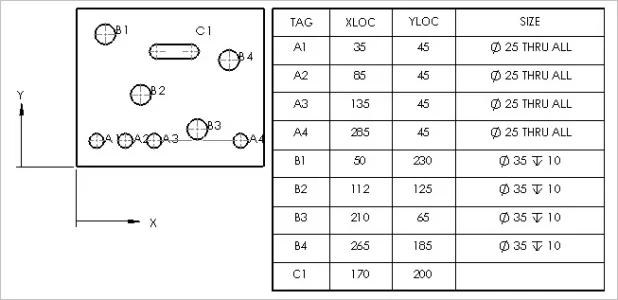

I need some parts made. I've made an attempt at CADing up what I need and have tried to produce a drawing, which should be attached to this post.

Just in case my drawing isn't clear: There are 6 counterbored holes to accept low profile M10 socket screws. Then there is an array of 3 by 13 holes that are threaded to accept M12-1.75 on 5cm centers.

I am going to need 7 of these. What I'm asking for is two fold:

- A quote on what someone here would want to make these for me. I'm flexible in that I can pick up and provide the steel (just want it out of vanilla hot rolled weldable..) or just pay for a finished product. The downside to this approach is that I double many hobbiests have a machine that have a 95cm long work envelope.

- Advice on how to make the drawing more standard. If I'm going to shop out for quotes on this part, I'd like to have the drawing have as little confusion as possible.

Thanks,

-W

First off, I have no idea what I'm doing

I need some parts made. I've made an attempt at CADing up what I need and have tried to produce a drawing, which should be attached to this post.

Just in case my drawing isn't clear: There are 6 counterbored holes to accept low profile M10 socket screws. Then there is an array of 3 by 13 holes that are threaded to accept M12-1.75 on 5cm centers.

I am going to need 7 of these. What I'm asking for is two fold:

- A quote on what someone here would want to make these for me. I'm flexible in that I can pick up and provide the steel (just want it out of vanilla hot rolled weldable..) or just pay for a finished product. The downside to this approach is that I double many hobbiests have a machine that have a 95cm long work envelope.

- Advice on how to make the drawing more standard. If I'm going to shop out for quotes on this part, I'd like to have the drawing have as little confusion as possible.

Thanks,

-W