-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Your preferred hold down fasteners?

- Thread starter Janger

- Start date

Brent H

Ultra Member

Hey John,

When I bought my mill i got a bit lucky as the seller included what worked out to 1.5 clamping kits. I received two trays, one complete with all the wedges and clamps and bolts etc and one that only contained the bolts and a couple coupler nuts. Both these sets are 1/2" and seem well suited for a standard Bridgeport or BP clone.

At work we have a 3/8 set for a smaller mill (Busy Bee 600). I also have some parts in the 3/8" at home for the lathe face plate

When I bought my mill i got a bit lucky as the seller included what worked out to 1.5 clamping kits. I received two trays, one complete with all the wedges and clamps and bolts etc and one that only contained the bolts and a couple coupler nuts. Both these sets are 1/2" and seem well suited for a standard Bridgeport or BP clone.

At work we have a 3/8 set for a smaller mill (Busy Bee 600). I also have some parts in the 3/8" at home for the lathe face plate

Chipper5783

Super User

Sized to the machine. Two 1/2" kits for the mid sized mills, a 3/8 kit for the little Maho. I've made a few custom Tee nuts for nearly every Tee slot ( because when you actually measure them, every one is different) - and sometimes an under sized stud or bolt is needed (3/8" on the larger mills, a 1/4" bolt in the middle of a part etc.).

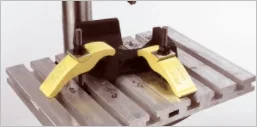

I have some metric tooling like RT where the casting lug dictates M# fastener therefore the T-nut must match, even though the table slot itself is capable of slightly larger. Same thing with some fixture plates I made for bolting into chucks, but I can bolt the plates themselves down to table. I use these Bessey style for setups because very fast to set up as long as the part isn't too high. Model 500 = 1/2" model 375 = 3/8". So the answer for me at least is: 'it depends' and a range.

I think most Asian Bridgeport clones have T-slot dimensions milled to Imp standards to mimic N-Am Bridgeport's (as opposed to actually being metric but close enough that the IMP works). I've never been able to verify. Anyways it pays to have a few different kinds kicking around but more dictated by the tooling & fixtures you strap on.

I think most Asian Bridgeport clones have T-slot dimensions milled to Imp standards to mimic N-Am Bridgeport's (as opposed to actually being metric but close enough that the IMP works). I've never been able to verify. Anyways it pays to have a few different kinds kicking around but more dictated by the tooling & fixtures you strap on.

Attachments

Side note - unfortunately this sort of question comes up too frequently. How do I put Humpty Dumpty back together again?

1/2" bolts are what like 7-14 ksi tension depending on the grade. Hobby grade cast iron is no match for excess gronk force like what a big commercial machine could withstand. You don't want things to move under machining forces especially interrupted cuts. But there is also no sense going nutty on clamping pressures. I've never actually seen a torque rating for mill tables, have any of you?

1/2" bolts are what like 7-14 ksi tension depending on the grade. Hobby grade cast iron is no match for excess gronk force like what a big commercial machine could withstand. You don't want things to move under machining forces especially interrupted cuts. But there is also no sense going nutty on clamping pressures. I've never actually seen a torque rating for mill tables, have any of you?

Not sure if this is the type info you are looking for Peter. Here is a Torque table for aluminum extrusion T-Slots. I have not found one for CI tables yet.

For a 5/16 T-nut it is 20 ft-lbs, so not a whole lot.

Here is the link to their website: https://faztek.net/technical.html

For a 5/16 T-nut it is 20 ft-lbs, so not a whole lot.

Here is the link to their website: https://faztek.net/technical.html