I got introduced to CA glue for metal work holding through Clickspring videos. I noticed his backing surface is almost never completely flat, he usually cuts a series of grooves to make annular rings. I always assumed this was more about reducing the surface area a bit & so that the bond wasn't too much of a good thing. He goes straight to the blowtorch or heat gun though for disassembly.

I'm not exactly sure what the painters tape is about. I'd like to hear if you guys have tried regular masking tape or other kinds of tape. I have a theory. CA ideally likes some degree of open porosity for good bonding. Two pieces of balsa wood bond aggressively & instantaneously with a small puff of dramatic exothermic smoke for good measure. Two pieces of hard plywood (denser, less porosity) is a slower reaction, typically has to be held clamped for a bit unless you use accelerator on one surface. Two pieces of metal (zero porosity) slower yet. In fact I've had metal parts fall off as I was turning in the lathe that were completely cured along the edge but still uncured in the middle. I wonder if the Clickspring mandrel grooves are more about allowing internal air gap to mitigate this? Maybe the painter tape is giving some porosity? It might also assist with peeling off glue residue which is a pita. There are much stronger double stick tapes, but the downside is they are designed to be permanent; quite impervious to solvents & heat can be a real mess as they wont let go until they are burning.

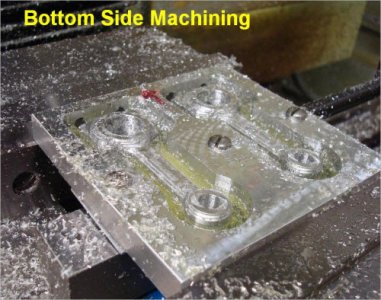

I was actually amazed NYC was able to get away with those cutting forces. Hogging on the upper edge of the tall block means he is putting tension on the glue joint. Glues are universally not great in tension, they are best in shear. So a thin part would stay put better than a thick part all things equal. I can see some down sides too. You can have a super CA bond between part & tape, but now you are entirely at the mercy of the tape's adhesive & the fixture plate. Generally painters tape (or tapes like that) use lower tack glue so it peels off easier & doesn't take underlying finish with it. Maybe its thin viscosity CA & its soaking in a bit? Clickspring uses quite thick viscosity CA, approaching a gel.

FWIW acetone will soften CA but its not nearly as effective solvent as what they specifically sell as de-bonder. Also, cutting fluids like the ones favored for aluminum including WD-40 are really effective at completely removing tape residue - and therefore can also work their way into a CA bonded joint & risk letting go while machining.

I dunno. I think CA for sure it has its place. But a cnc shop on a large part? You can buy 10 Mitee-Bite clamps for $50 & swap in a part faster than you can tape & spread glue, nevermind glue cleanup or risking a $$ part or $$$ cutting tool flying off?