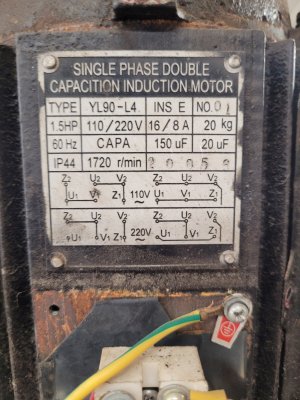

A few years back one of the long time machine and welding shops (Frank's) shut down for owner to retire. I wanted some momento but was out of country for the sale, so had my wife buy a milling machine and band saw. The mill is a little vertical dovetail Zay 7045FG. Chinese made I assume but if Frank had it (he rebuilt machine tools) not likely a bad machine. Problem is: it is wired 110V and at 2HP it pushes past a 20A breaker if heavily loaded, so I need to switch 20 220V. I work with a bunch of EEs, CETs and electricians and NONE of them can figure out what the really bad wiring diagram on the motor plate shows for conversion of voltage. The diagram tells you which terminal on the connection block is connected to what jumpers and SOME of the external wires, but not all (4 wire motor as reversible).

So, I need to contact someone who sold these things originally to get the mystery solved (unless someone here has any answer).

So, I need to contact someone who sold these things originally to get the mystery solved (unless someone here has any answer).