Hello everyone, I'm new here.

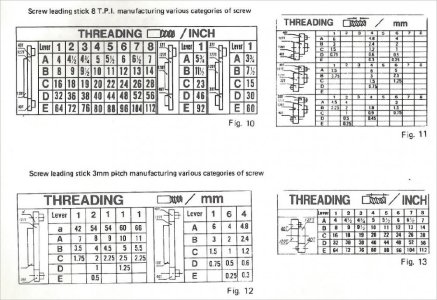

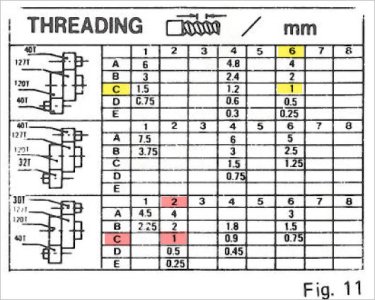

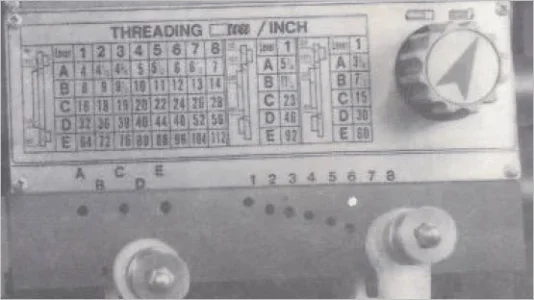

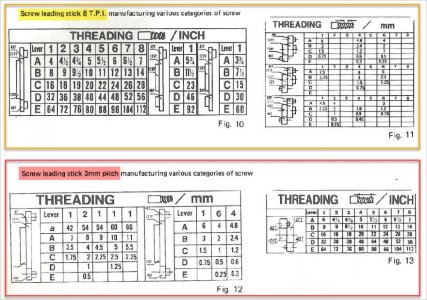

I really need help deciphering a 35 plus year old King 14x40 lathe's metric threading chart. I lost the manual a long time ago in a fire. It didn't help much anyways as it was a direct translation of the Taiwanese speak so it made little sense to me. So, I can make out the gears and their required position, but since I want to make a 1 mm thread pitch(per rev) on a shaft , where do I start?

Take a look at the picture. This is so odd.

Any help will be greatly appreciated.

I really need help deciphering a 35 plus year old King 14x40 lathe's metric threading chart. I lost the manual a long time ago in a fire. It didn't help much anyways as it was a direct translation of the Taiwanese speak so it made little sense to me. So, I can make out the gears and their required position, but since I want to make a 1 mm thread pitch(per rev) on a shaft , where do I start?

Take a look at the picture. This is so odd.

Any help will be greatly appreciated.