In GTA or close proximity to L4G7X4.

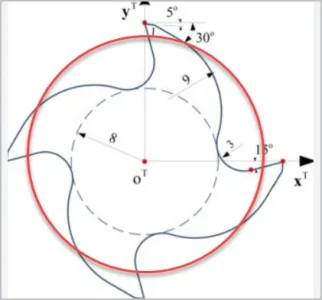

I need 1 degree angle on flute, 5mm and 6mm on tip, flute length at least 20mm but longer is better?

I tried the common machine shop supplies (KBC for example), most of them have 1 deg and tip 3/16" (too small) and 1/4" (too large).

I need to fix these conical holes in .22 and .25 pellet sizer, this how I got them from a maker, I don't want to return but fix it - needs to be smooth and shiny.

I need 1 degree angle on flute, 5mm and 6mm on tip, flute length at least 20mm but longer is better?

I tried the common machine shop supplies (KBC for example), most of them have 1 deg and tip 3/16" (too small) and 1/4" (too large).

I need to fix these conical holes in .22 and .25 pellet sizer, this how I got them from a maker, I don't want to return but fix it - needs to be smooth and shiny.