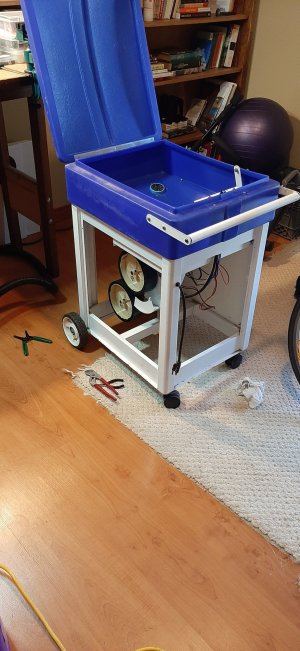

I am working on a squash ball machine, like a tennis ball machine. It has two DC motors direct driving two wheels, spinning in opposite directions. The balls drop through flaps in the feeder, down a path to the wheels, and are projected to the front or side wall to become the start of a drill of some sort. I found out it was not working. Feeling pretty handy, I offered to fix it, thinking that it would be an easy fix. What I found was one of the motors did not work, and upon disassembling it, found most of the windings broken at the commutator, where they wrap around. It was kind of bizarre. I have never seen that before. I tried to track down a replacement motor but no luck. This one appears to be a unicorn. A local motor shop said they could send it out cause they don't do motors that small but it would be several (5) hundred dollars so the project was shelved for a few years, but, recently, a friend offered to fix the motor. I thought he was going to rewind the motor but he actually repaired each break and then epoxied over them for support. It might actually work. After putting it all back together today, I found that the top wheel, the one that had the broken windings, has more vibration than the lower motor/wheel assembly. There is a metal hub but the wheels are plastic, and looks like some kind of a glued on rubber surface on them. I am thinking that the vibration might have caused the windings to break. I also wonder if the shock of the squash ball getting wedged between the two wheels, squished, and then thrown out might have contributed to it too. I don't think it is a great design, and not a great build.

Now you have the back story. How does one balance such a wheel? Can I dynamic balance it at home or can I only expect a static balance of some sort? It looks like tape on the inside hub of the wheel and I suspect this was an attempt on balancing them, maybe weights under? The plastic that goes around the center hub, which is metal and contains the set screw have some cracks in them so I am planning on putting a sleeve over them to stop any further cracking. I have balanced lawn mower blades after sharpening but not much else in wheels. Suggestions?

I should add that I switched wheels top and bottom and the vibration followed the wheel.

Thanks

Now you have the back story. How does one balance such a wheel? Can I dynamic balance it at home or can I only expect a static balance of some sort? It looks like tape on the inside hub of the wheel and I suspect this was an attempt on balancing them, maybe weights under? The plastic that goes around the center hub, which is metal and contains the set screw have some cracks in them so I am planning on putting a sleeve over them to stop any further cracking. I have balanced lawn mower blades after sharpening but not much else in wheels. Suggestions?

I should add that I switched wheels top and bottom and the vibration followed the wheel.

Thanks