-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

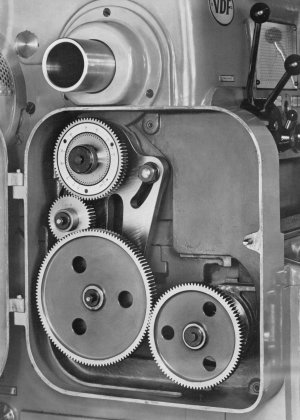

What is this gear?

- Thread starter YotaBota

- Start date

Yes, it is the main drive gear of the feed/threading gearbox. On can move the gear in relation to its drive shaft to, for example, create multi start threads.

This feature could also be used to cut multi fluted parts.

Say you start with the gear at 0* and thread 8 TPI. After that thread is finished, move the gear to the 180* position and thread again at 8 TPI. The result will be a 16 TPI, two start thread. If you only moved 90* and did this four times, you’d end up with a 32 TPI, 4 start thread.

This can be done with just about any lathe as long as the gear’s # of teeth is divisible by the number of thread starts you try to cut. One would have to mark some references on the gears to get it right, but it can be done. Leave the feed in the headstock engaged to do this and advance the gear train by the required # of teeth and remount the gear.

The other way to cut multi-start threads is to use the compound parallel to the Z-axis and advance/retract it the correct distance for the TPI you are cutting. All the threading is done by plunging with the cross slide in that operation.

Steve Summer’s Hendey Lathe has a lever to disengage/engage the feed gear to produce multi start threads. He has a video where he explains this feature.

This feature could also be used to cut multi fluted parts.

Say you start with the gear at 0* and thread 8 TPI. After that thread is finished, move the gear to the 180* position and thread again at 8 TPI. The result will be a 16 TPI, two start thread. If you only moved 90* and did this four times, you’d end up with a 32 TPI, 4 start thread.

This can be done with just about any lathe as long as the gear’s # of teeth is divisible by the number of thread starts you try to cut. One would have to mark some references on the gears to get it right, but it can be done. Leave the feed in the headstock engaged to do this and advance the gear train by the required # of teeth and remount the gear.

The other way to cut multi-start threads is to use the compound parallel to the Z-axis and advance/retract it the correct distance for the TPI you are cutting. All the threading is done by plunging with the cross slide in that operation.

Steve Summer’s Hendey Lathe has a lever to disengage/engage the feed gear to produce multi start threads. He has a video where he explains this feature.

I built an indexer(ish) using a 60 toothsaw blade on an arbor fit to the spindle and a pointer attached on the headstock. It worked but it wasn't convenient either.

What is it that you are trying to do?