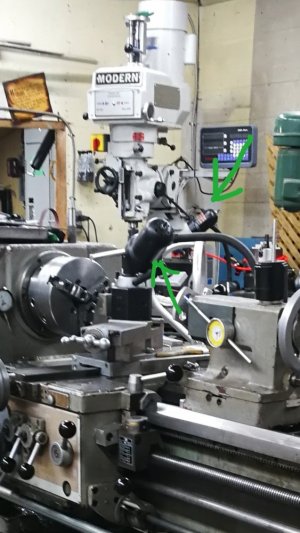

This topic has been discussed before, but it's probably good to revisit as people's needs change. I'm more of a fabricator than machinist, so it's about portability to me. Most of my machines aren't against a wall. But I do need good lighting for occasional lathe or mill work.

I ditched most of my task lighting solutions years ago, with the exception of an old balanced arm / floating arm / "Angelpoise" lamp shared by three stationary machines retrofitted with an LED bulb. Now I use portable Milwaukee LED sources including a tripod light, portable task light and portable spot. All are LED and all battery powered. The big Rocket light can also be cord powered if need, but a 12 AH battery keeps it working all day. I use it at the drill press and mini mill, but all move it into position when using a mag drill on a 12' piece of tubing on sawhorses in the driveway. They are all pricey, but I don't need anything else. The advantage is I can position them anywhere in the shop, get them into things for out-of-position welding and fabrication, or put them under a truck to work on as needed. They travel to job sites too.

It's all about your needs. Anything that isn't portable for fabrication is practically useless, but the opposite is true for machining for most people I suspect. Either way, it's hard to think of a major disadvantage to LED over other sources these days. Even costs have come enough to crush the cost argument. Having said that, I did see an episode of

Homestead Rescue on TV the other night where Marty Raney used an incandescent light bulb for a heat source inside a pumphouse. So...there's that.