-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you guys using for lathe threading tools?

- Thread starter YYCHM

- Start date

140mower

Don

So far for me, only hand ground hss, both internal and external. Not long ago I picked up a bunch of "loose" tooling and assorted sundries of which I think there's insert holders and bits for both but haven't tried them yet.

I did the 1.5" 8tpi internal threads in 4340 when I made my collet chuck with the hss and can't imagine how carbide would have done better...... I have quite a lot of hss in various sizes, so I had better keep liking it for a few more years. Lol.

I did the 1.5" 8tpi internal threads in 4340 when I made my collet chuck with the hss and can't imagine how carbide would have done better...... I have quite a lot of hss in various sizes, so I had better keep liking it for a few more years. Lol.

I use any one of the following tools, depending on the application. I like the fact that I can buy an insert for a particular thread profile, and know that it is 100% true to form. I have used 60*, 55*, acme, and trapezoid inserts. Most often, of course, is the 60*. The inserts are non-topping, this way I can use the one insert to do various pitches. I have done square threads, but used HSS, hand ground, which for me took forever to get it correct.

Attachments

I have purchased few carbide insert threading tools but I don't like them. A few years ago I ran across this kit.

I never looked back. This tool cuts the best threads I know how to make. It uses hss inserts instead of carbide. So you can cut slower and still get a fantastic finish and not have to grind any hss - although you can if you want to.

I also have one of these from Mesa tool. It is almost as good as the Warner but uses carbide inserts. I use it for most of the threading I do and I save the Warner for those times when I need the best thread I can make.

www.mesatool.com

www.mesatool.com

Yes, they are both a bit pricey. But crappy threads are a nightmare. You can make your own hss threading tools or you can buy carbide or you can get the Warner tool and never look back.

Kit #18 1/2 inch Threader NV

www.arwarnerco.com

I never looked back. This tool cuts the best threads I know how to make. It uses hss inserts instead of carbide. So you can cut slower and still get a fantastic finish and not have to grind any hss - although you can if you want to.

I also have one of these from Mesa tool. It is almost as good as the Warner but uses carbide inserts. I use it for most of the threading I do and I save the Warner for those times when I need the best thread I can make.

1/2" Dia. Thread & Grooving Tool ID/OD | mesatool

1/2"″ Thread & Groove ToolThread ID/OD forwards, backwards, upside down.Cutting edge of insert is on centerline!Actual size: ..498 dia X 4.5″ long, flats on 4 sides.Min bore is .650.Heat treated tool steel with black oxide coating.Threading inserts are .093 wide, good for 11 TPI & up.Comes with...

Yes, they are both a bit pricey. But crappy threads are a nightmare. You can make your own hss threading tools or you can buy carbide or you can get the Warner tool and never look back.

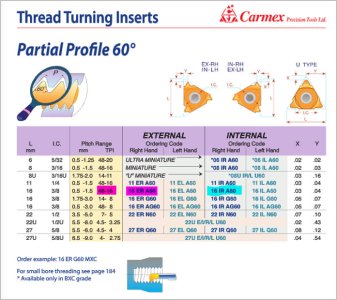

I don't have a ton of threading experience but these are AliExpress clones of Carmex...kinda. No issues, I like them. These parts are stainless & direction was into chuck so selected slowest speed on my lathe. I've used HSS too but on finer threads its a bit fussier to get the geometry & point just right. So depends on your application. Note internal threading inserts are different.

Attachments

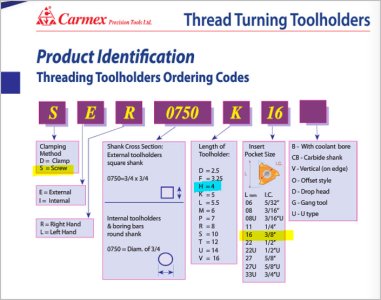

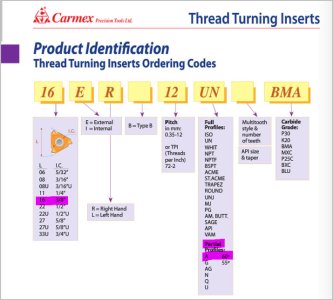

Selecting the imports can be highly confusing because they don't always adopt standard nomenclature or have different nomenclature, so spend some time reading the fine print. If it seems ambiguous, go to a different seller, often times they don't even know what they are selling themselves. Carmex for example has an extensive & detailed catalog that you can at least get a feel for the terminology. But they they are Mucho Spendo

Attachments

Tom Kitta

Ultra Member

I use both HSS and inserts. Both have plus and minus. Internal threading can be done with HSS but can be... challenging - depending on exact setup you have. I have a blank ground by some very patient man (or a woman) that has a little triangle of HSS at the very end and is skinny for over an inch. Someone took like an hour or so to grind this internal threading tool.

Overall, mostly HSS. I had been using a criterion bar & inserts for internal threads recently, but justs snapped two in a row doing a fairly coarse thread (56.7mm x 3mm). Ugh. The problem with carbide thread cutting tools, in my experience anyway, on a manual machine is speed - carbide can be really brittle especially with a wide, slow cut. On a manual machine where you have to stop things before they crash at the end of a thread, speed is all but impossible. CNC obviously does have this issue.

I've a tool and cutter grinder and use it to grind threading tools on it. i did my 25 year penance doing it by hand, but the grinder is oh so nice. You spark out and get a mirror finish, no need for stoning after grinding to get a great edge and 60 is exactly 30 off the side - i.e. you can set the tool alignment up with a small square.

Over the years I've collect and made numerous hss internal tools, Craig I will try to get some photos to give some ideas. Easiest of course are larger ones that permit a tool held in the end of a bar....just like an external tool but shorter.

I've a tool and cutter grinder and use it to grind threading tools on it. i did my 25 year penance doing it by hand, but the grinder is oh so nice. You spark out and get a mirror finish, no need for stoning after grinding to get a great edge and 60 is exactly 30 off the side - i.e. you can set the tool alignment up with a small square.

Over the years I've collect and made numerous hss internal tools, Craig I will try to get some photos to give some ideas. Easiest of course are larger ones that permit a tool held in the end of a bar....just like an external tool but shorter.

Last edited:

You guys that like HSS, please post some pics of the internal threading tools you have ground.

Thanks,

Craig

I'll post a few that I ground myself later this morning when I go out to the shop - if I can find them. What I can say right now is that they are a pain in the bunnion. A lotta grinding.....

In the meantime, note that both of the two tools I posted above do both internal and external threads. One end is internal and the other end is external.

DPittman

Ultra Member

While your gathering pics.....I'd like to see what you use as a tool and cutter grinder. Please and thank you.Overall, mostly HSS. I had been using a criterion bar & inserts for internal threads recently, but justs snapped two in a row doing a fairly coarse thread (56.7mm x 3mm). Ugh. The problem with carbide thread cutting tools, in my experience anyway, on a manual machine is speed - carbide can be really brittle especially with a wide, slow cut. On a manual machine where you have to stop things before they crash at the end of a thread, speed is all but impossible. CNC obviously does have this issue.

I've a tool and cutter grinder and use it to grind threading tools on it. i did my 25 year penance doing it by hand, but the grinder is oh so nice. You spark out and get a mirror finish, no need for stoning after grinding to get a great edge and 60 is exactly 30 off the side - i.e. you can set the tool alignment up with a small square.

Over the years I've collect and made numerous hss internal tools, Craig I will try to get some photos to give some ideas. Easiest of course are larger ones that permit a tool held in the end of a bar....just like an external tool but shorter.

I've got two (yeah I know, but they just somehow find a path to my door). They are both Chevelair. The big one was small dollars and I did a ground up scraping job on it and its perfect. It gets used mostly for cylindrical grinding and a little bit for horizontal milling cutters. 95% of the time its a light duty cylindrical grinder with flood which is a super useful thing to have in the shop. The smaller benchtop machine has an air bearing that mostly gets used for end mills, lathe tools and drills. I may start a thread on them if you want to see them, just don't want to overwhelm Craig's threading tool thread with my grinder pics.

Former Member

Guest

The issue of crash is controlled by direction of cut, away from the shoulder to prevent crash and start in a recess beside the shoulder (always visible on old machinery). The direction is controlled by rotation direction pure and simple. CNC has made machinists lazy in thinking out the solution.Overall, mostly HSS. I had been using a criterion bar & inserts for internal threads recently, but justs snapped two in a row doing a fairly coarse thread (56.7mm x 3mm). Ugh. The problem with carbide thread cutting tools, in my experience anyway, on a manual machine is speed - carbide can be really brittle especially with a wide, slow cut. On a manual machine where you have to stop things before they crash at the end of a thread, speed is all but impossible. CNC obviously does have this issue.

I've a tool and cutter grinder and use it to grind threading tools on it. i did my 25 year penance doing it by hand, but the grinder is oh so nice. You spark out and get a mirror finish, no need for stoning after grinding to get a great edge and 60 is exactly 30 off the side - i.e. you can set the tool alignment up with a small square.

Over the years I've collect and made numerous hss internal tools, Craig I will try to get some photos to give some ideas. Easiest of course are larger ones that permit a tool held in the end of a bar....just like an external tool but shorter.

Now the only question becomes how to ensure your chuck doesn't come off, does your lathe run in reverse and how to mount the tooling to ensure proper load transfer during threading (back side or front side) and finally how this effects your set ups and operation.

How fast do you manually thread at? I agree its sensible to control direction to avoid a crash, however the issue I highlighted is a wide cut (coarse thread) at slow speed with carbide, not the crash. Sometimes its just a lot easier with hss and frankly, at manual threading speeds, much of the benefit of carbide tooling isn't there in the first place. For example, you often want to retract the tool so the thread ends at the right spot....requires speeds less than 100 imo on a manual lathe.

Last edited:

I never got into threading in reverse away from the chuck, but i'm going to give it a shot. I was making a small drill chuck arbor yesterday and crashed into the shoulder at about 100 rpm cutting the 1/2" 20tpi. Just wasn't quick enough with the half nut and didn't have much of a gutter and as soon as it hit, i couldn't release the half nuts. So now i need to build a rear toolpost.

Other than that, i use a mix of both HSS and carbide insert tooling. HSS is sharper and needs less pressure, so it works better on small diameter, finer thread stuff.

Other than that, i use a mix of both HSS and carbide insert tooling. HSS is sharper and needs less pressure, so it works better on small diameter, finer thread stuff.

Limited thread experience here, all 60*, some HSS, some insert. My next adventure is going to be square or trap threads, internal and external. I've been stockpiling inserts/holders from Aliexpress for several months in preparation. My single point cutter from Aliexpress is very nice for grinding HSS. Fit/finish it is sloppy, but fixable over time. I like low speed, and if I can replace the cross feed lead screw/nut on my von-wyck lathe it will be the goto as it will do ~28 rpm in back-gear.

I use the Joe Pie method for threading away from the chuck, no rear tool post required. I use the Mesa tool like Sasquatch most of the time but for non 60 degree I hand grind HSS

Last edited: