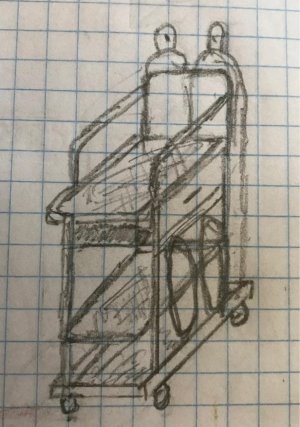

A while back I bought a warehouse cart to repurpose into a welding cart for my MIG and TIG machines.

I cut it into pieces so it was easier to store till I got at it.

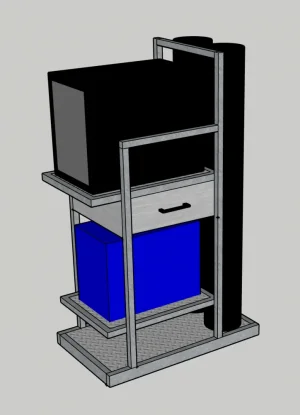

Tonight I started by cutting the shelves apart so I could preserve the rounded corners. I then welded the narrowed parts back together.

Went pretty well.

I cut it into pieces so it was easier to store till I got at it.

Tonight I started by cutting the shelves apart so I could preserve the rounded corners. I then welded the narrowed parts back together.

Went pretty well.

Last edited: