Xyphota

Ultra Member

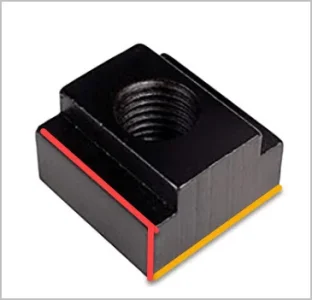

This is going to sound very dumb, but title says it all.

I finally reassembled my new-to-me mill which included a vise and a bunch of hold down accessories, and I just realized that the seller only included one t-nut, so I cant even hold down my Vise.

Now of course purchasing more T-nuts is the sensible solution, but don’t T-nuts seem like the perfect first milling project? Haha.

So I’d like to borrow one or two T-nuts (5/8” Table Slot Width) from a fellow Calgarian, fabricate a handful of them and then return them.

EDIT: Clarity

I finally reassembled my new-to-me mill which included a vise and a bunch of hold down accessories, and I just realized that the seller only included one t-nut, so I cant even hold down my Vise.

Now of course purchasing more T-nuts is the sensible solution, but don’t T-nuts seem like the perfect first milling project? Haha.

So I’d like to borrow one or two T-nuts (5/8” Table Slot Width) from a fellow Calgarian, fabricate a handful of them and then return them.

EDIT: Clarity

Last edited: