So, I may not be the best to answer this - I've had a lathe for decades and a smaller mill drill for years, but I'm new to a bigger mill, but I'll add my two cents.

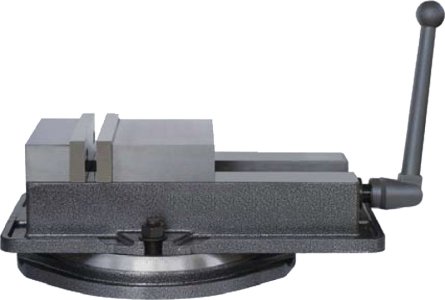

I bought a swivel vise for the mill drill - never ever used the swivel feature except to tram the vise. Tramming is better done without.

The big mill came with a used non-adjustable GS vise. I love it.

I suppose an application might arise where the swivel feature might come in handy, but I think I can always use the T-slots to mount a non-swivel vise on an angle when that time comes if it ever does.

All that is to say that my advice is to skip the swivel & tilt features and put the money into a better standard non-adjustable vise. Better to have a better vise for the money than something that is more flexible but isn't as good and will never get used.

You can always find other ways to mount the vise and parts to get what you need, but you can't make a multi-function vise into the better vise you could have had for the same money.

Now, if I knew for sure that I would be swinging my vise back N forth every day I used it cuz I was constantly making hex devices of some kind, I might feel differently. Then again, I'd prolly make a fixture to use on my regular fixed vise anyway........

So ya, skip the adjustable vise and put your money toward a better fixed vise.