-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vfd question

- Thread starter 05plsrt4

- Start date

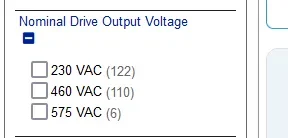

Don't know of many VFD's that deal with voltage conversion like that.Does anyone know if i can run a 3 phase 320v coolant pump off 220 single phase using a vfd?

Were it me, I'd hook a VFD to the pump and have a go, to see what it does. May run adequately for use, with a 3 ph 220v feed. May need a tweak or so, on some of the settings to stop it alarming out, if it does (alarm out, that is).

Admittedly, talking at least 'partly' outta my behind here, so take that as you may, but a higher voltage motor, of a given frame size and power output, is going to have finer windings than a lower voltage motor, no?

What is this motor on? Horsepower/wattage? Seems a bit of a bastard Voltage, unless it has to do with winding differences (Star/Delta) voltage ratings on some Euro machinery.

Personally, I'd spend the money on a single phase motor and hack it in to the system, rather than spend the buck on a VFD for a coolant pump.

What is this motor on? Horsepower/wattage? Seems a bit of a bastard Voltage, unless it has to do with winding differences (Star/Delta) voltage ratings on some Euro machinery.

Personally, I'd spend the money on a single phase motor and hack it in to the system, rather than spend the buck on a VFD for a coolant pump.

Does anyone know if i can run a 3 phase 320v coolant pump off 220 single phase using a vfd?

Off hand, I'd advise against it. The lower voltage will be really hard on the motor. It might work but it might also be a nightmare.

Using a vfd is an expensive solution anyway. You can prolly get a 220 or even 110 single phase motor to do that job dirt cheap by comparison. Just watch out for rpm.

330 is a rather odd voltage in North America. I've only ever seen it in imported hardware. Are you sure it's not a badly typed number and is really 220 not 330?

If you have access to 3 phase supply of any voltage, a transformer would work fine.

Quick Digi-Key and eBay search for suitable transformers, nothing inexpensive at the moment. Swapping the motor might be the least expensive option.

Saw your interim original posts and this replacement. Made me wonder what you were thinking. Were you assuming he had access to 220 3 phase? If so, cool idea to use what I think was three separate transformers! The link was gone before I could look at it....

You type faster than I can read.......

The problem im running into is that its a very unusual round base pump that fits in a very specific spot in the machine. Theres alot of stuff in the way where the pump is placed. Ive measure other pumps and without extensive modifications i wont be able to get an off the shelf pump to work. Rewinding it is just too expensive.

i may end up ordering a euro pump that is 220 three phase and using the vfd to run it.

the pump is 550/320v. I was unsure if it could be run off a vfd on lower voltage

i may end up ordering a euro pump that is 220 three phase and using the vfd to run it.

the pump is 550/320v. I was unsure if it could be run off a vfd on lower voltage

The problem im running into is that its a very unusual round base pump that fits in a very specific spot in the machine.

Nasty problem if you ask me.

But maybe you can find another motor with that voltage and use it to create a small rotary generator instead....... If not, then a different voltage and transformers. Either way, basically your own custom 320V RPC.

550 shouldn't be too hard to find.

Or maybe an external pump with oil lines running to where you need them?

trlvn

Ultra Member

its a coolant pump for a schaublin milling machine. 0.14hp. I didn’t know if would run it but just not have the same rpm’s and power.

the pump is 550/320v. I was unsure if it could be run off a vfd on lower voltage

A picture of the motor tag or wiring info might be useful. I believe that 380V 3PH is common in Europe; never heard of 330 volts before. Is it possible the middle digit is an "8"?

OTOH, I believe 550/575/600 volts is pretty much ONLY a Canadian thing? See the long table of voltages by country at:

Mains electricity by country - Wikipedia

Also, Europe is mostly 50 hz AC v. 60 hz in North America. If you run a 50 hz motor on 60 hz, typically it will run 20% faster than designed. I doubt that would make a difference for a pump. Probably?

My understanding is that if you run a motor on lower than its design voltage, it will tend to draw more amps and thus create more heat. Thus shortening the life of the motor. Sometimes directly to zero!

What are the electrical specs on the main motor?

Craig

Have it rewound. That's what I did for my milling machine. I went from 600v/3p to 220/3h, and matched it up with a VFD.

Dabbler

ersatz engineer

@Susquatch 330/340V is common in the US south in industrial areas. I've seem several largish mills wired for 340V from Kentucky and Louisiana. They usually are multivoltage motors, however. @trevj are you sure this motor cannot be wired for 340/480V? Then you can use a voltage doubling VFD...

Otherwise I agree it might be cheaper to replace the motor, if possible. At least in Calgary you'd be hard pressed to find anyone to do a motor rewind.

Otherwise I agree it might be cheaper to replace the motor, if possible. At least in Calgary you'd be hard pressed to find anyone to do a motor rewind.

Not my motor, so have no real idea.@Susquatch 330/340V is common in the US south in industrial areas. I've seem several largish mills wired for 340V from Kentucky and Louisiana. They usually are multivoltage motors, however. @trevj are you sure this motor cannot be wired for 340/480V? Then you can use a voltage doubling VFD...

Otherwise I agree it might be cheaper to replace the motor, if possible. At least in Calgary you'd be hard pressed to find anyone to do a motor rewind.

The only place I have seen doing rewinds, is some back alley shop in India, on youtube! Usually by a guy with bare feet, working on a dirt floor!

Says on the label that the HP is .14, which is more or less, 1/7th of a HP. I would find it tough to figure that there are not some single phase fractional HP motors out there that could not be subbed in.

Ironman

Ultra Member

Yes you can run a 340 volt pump on 220 3 phase.

I have run a 3 hp 600 volt motor on 220 3ph. It starts, runs and achieved rated rpm, but it had considerably less power than on 600v.

I'm sure that someone can calculate it out but who cares, a coolant pump is not working hard.

I have run a 3 hp 600 volt motor on 220 3ph. It starts, runs and achieved rated rpm, but it had considerably less power than on 600v.

I'm sure that someone can calculate it out but who cares, a coolant pump is not working hard.

It's been a while since I followed this project. My STMBL is working fine but at a lower voltage than 320V. Also the original driver integrated circuit was discontinued and I don't know if a new one was found.

However, as an open source project it's quite possible that someone on the forum might be able to help.

github.com

github.com

However, as an open source project it's quite possible that someone on the forum might be able to help.

stmbl/docs/src/Getting Started.adoc at master · rene-dev/stmbl

AC Servo Driver for STM32F4. Contribute to rene-dev/stmbl development by creating an account on GitHub.

Oh and I've posted that photo of the motor to Donald Chen at Bergerda. Asked him if one of his AC Servo drives would work.

What might be the cost of such? Given that he OP is watching price pretty carefully, it seems a possibility, if the price is low enough once a driver/power supply is factored in.Oh and I've posted that photo of the motor to Donald Chen at Bergerda. Asked him if one of his AC Servo drives would work.

As far as compact, with power, I have seen a fair few model airplane electric motors that provided that kind of horsepower in far smaller packages, though, admittedly, at high RPM's.