curmudgeon

(Steve)

Grrr, the tailstock quill on my Grizzly G0602 10x22 is making me cranky. Extending/retracting the quill is so stiff that it is effectively unusable for drilling.

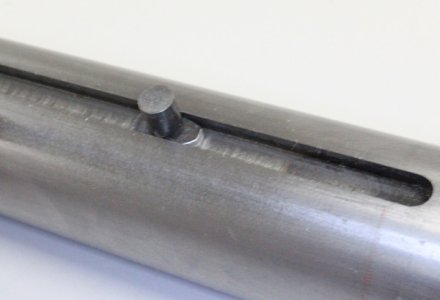

Here's a pic from the manual:

There's a slot along the backside of the casting, and the quill lock lever squeezes the casting around the quill. With the help of a mallet I can force the quill out of the casting. Neither the outside of the quill nor the bore of the casting is scratched up.

By tapping a wedge into the front of the slot in the tailstock, I can easily insert the quill about 1/2 ways in, but after removing the wedge the casting springs back to a "too tight" fit. It's as if the quill had been removed and the guerilla tightened the lock lever as tight as possible and left it that way for a decade.

I would love to spring it open so that it slides nicely, but I am super worried about cracking the casting.

- how worried should I be about using a wedge to open up the slot?

- would it be smarter to try and hone the bore of the casting?

- are there better options?

Thanks!

Here's a pic from the manual:

There's a slot along the backside of the casting, and the quill lock lever squeezes the casting around the quill. With the help of a mallet I can force the quill out of the casting. Neither the outside of the quill nor the bore of the casting is scratched up.

By tapping a wedge into the front of the slot in the tailstock, I can easily insert the quill about 1/2 ways in, but after removing the wedge the casting springs back to a "too tight" fit. It's as if the quill had been removed and the guerilla tightened the lock lever as tight as possible and left it that way for a decade.

I would love to spring it open so that it slides nicely, but I am super worried about cracking the casting.

- how worried should I be about using a wedge to open up the slot?

- would it be smarter to try and hone the bore of the casting?

- are there better options?

Thanks!