1018Machine

Well-Known Member

Being new here I figured I make my first post to introduce myself. After sifting through the forum I've come to learn there are many members "north" of the border posting here which is nice to see. I too reside in SWO and mostly make custom fishing reels and the last few years have been dabbling in watch making although the primary work in my shop revolves around reels.

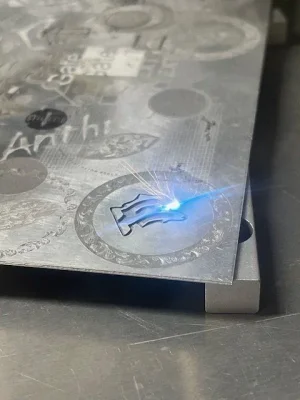

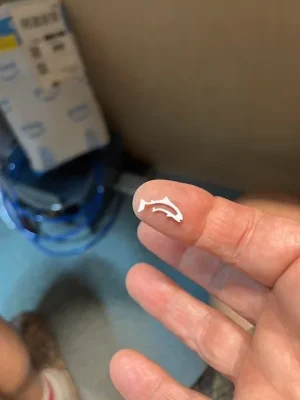

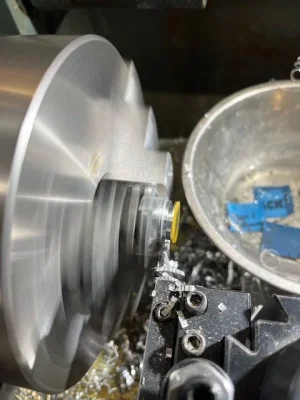

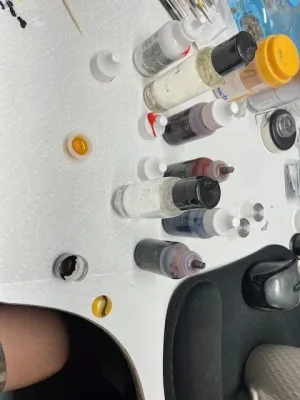

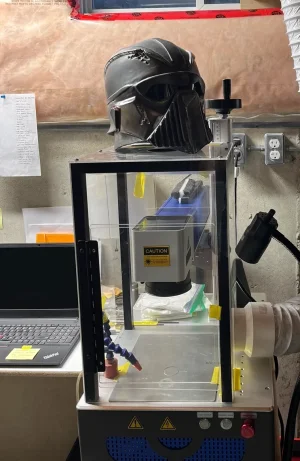

I thought I'd share a small project I just finished for one of those reels were the customer wanted a Tigers eye "look" for the cabochon that covers the tension dial on the backplate. Casting resins have always been a hit and miss for me so this time I figured I'd try UV resin! I must say it performs well and machines nicely too. The best thing is it's instant and you can move on with the project immediately. The inside component of the cabochon has my logo icon as it always does and this time I cut it out on using my fiber laser. Here's some pics of the project.

Thanks for looking!

I thought I'd share a small project I just finished for one of those reels were the customer wanted a Tigers eye "look" for the cabochon that covers the tension dial on the backplate. Casting resins have always been a hit and miss for me so this time I figured I'd try UV resin! I must say it performs well and machines nicely too. The best thing is it's instant and you can move on with the project immediately. The inside component of the cabochon has my logo icon as it always does and this time I cut it out on using my fiber laser. Here's some pics of the project.

Thanks for looking!