This is a project that I'm still working on .

Appears to be a Craftex CX603 ( current model ) , there is no name on it just a serial number stamped under the table and a decal under the belt cover indicating spindle speeds .

I don't know any history on the machine as I bought it from a school board auction, apparently it went thru one auction and wasn't purchased so I picked it up for scrap price .

It had NO electronics with it but it has ball screws on all 3 axis and 3 stepper motors as well as a 1 HP , 90 volt DC motor for the spindle . It appears to have been originally a CNC machine as there is no quill feed or quill lock and the quill lock hole isn't even bored . It is an R8 spindle .

I had a DC drive control so that is now working .

I found an article on the net for making variable speed / reversible controls for the X , Y ,Z axis so they are powered up . I'm not interested in making it CNC but at least the drives are powered .

I use a computer power supply for the electronics and the steppers are powered by 3 separate 30 volt power supplies.

Machine at present

90volt power supply and Bijur style oiler

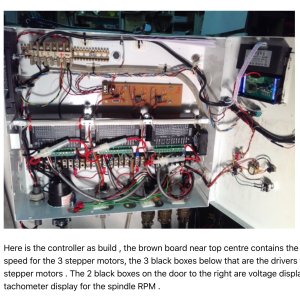

Stepper motor controls and pendents

Ball screw and stepper motor .

I also have a millrite mill , south bend lathe , converted wood to metal bandsaw and a surface grinder that I'm just starting on .

Bill

Appears to be a Craftex CX603 ( current model ) , there is no name on it just a serial number stamped under the table and a decal under the belt cover indicating spindle speeds .

I don't know any history on the machine as I bought it from a school board auction, apparently it went thru one auction and wasn't purchased so I picked it up for scrap price .

It had NO electronics with it but it has ball screws on all 3 axis and 3 stepper motors as well as a 1 HP , 90 volt DC motor for the spindle . It appears to have been originally a CNC machine as there is no quill feed or quill lock and the quill lock hole isn't even bored . It is an R8 spindle .

I had a DC drive control so that is now working .

I found an article on the net for making variable speed / reversible controls for the X , Y ,Z axis so they are powered up . I'm not interested in making it CNC but at least the drives are powered .

I use a computer power supply for the electronics and the steppers are powered by 3 separate 30 volt power supplies.

Machine at present

90volt power supply and Bijur style oiler

Stepper motor controls and pendents

Ball screw and stepper motor .

I also have a millrite mill , south bend lathe , converted wood to metal bandsaw and a surface grinder that I'm just starting on .

Bill