I made a pair of identical chuck keys specifically for setting up my 4-jaw chuck. Not my idea, I saw it somewhere. But it works quite well because you can adjust the opposing jaws simultaneously in unison while watching the dial & just converge on the target with both jaws tight. Its easier to do than explain but saved me set dial-in time because normally I am slow as a tortoise.

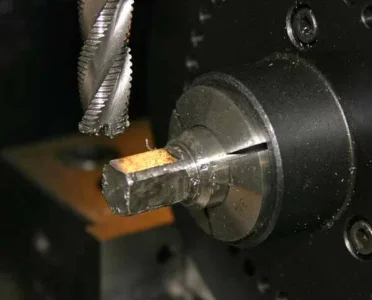

I found a piece of mystery metal that was 0.750" & shiny - always a dangerous sign It wasn't magnetic so I knew it was stainless. But this was some weird, tough sh*t for some reason. Long, hot, curly, razor sharp swarf came off at the lathe. Turning, drilling, milling & tapping the stuff was just brutal compared to mild steel & fighting me every step. It seemed much tougher than any stainless I've tried before. Hey is titanium non-magnetic? DOH! Oh well, used up the scrap & it wont rust. Initially I was going to make a knob but didn't like how it looked so went the tommy bar route.

It wasn't magnetic so I knew it was stainless. But this was some weird, tough sh*t for some reason. Long, hot, curly, razor sharp swarf came off at the lathe. Turning, drilling, milling & tapping the stuff was just brutal compared to mild steel & fighting me every step. It seemed much tougher than any stainless I've tried before. Hey is titanium non-magnetic? DOH! Oh well, used up the scrap & it wont rust. Initially I was going to make a knob but didn't like how it looked so went the tommy bar route.

Notice my goof up, the tommy bar is not aligned to the square facets. Oops. Then I looked at my other commercial chuck keys - neither are they! Haha. So its a design enhancement, not a screw up.

I found a piece of mystery metal that was 0.750" & shiny - always a dangerous sign

Notice my goof up, the tommy bar is not aligned to the square facets. Oops. Then I looked at my other commercial chuck keys - neither are they! Haha. So its a design enhancement, not a screw up.