LRSbm146

Member

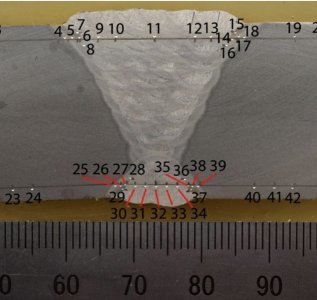

Everyone knows a tig welder needs to have a tungsten holder and I’ve seen some pretty elaborate ones over the years. Working with a couple guys that have been using plastic drill bit sleeves, so I whipped up a couple before Christmas out of aluminum and carbon fiber. Not that durable but turned out pretty good so made one more for myself but used a piece of titanium that’s been laying around my garage. This was my first time turning titanium....

Not a very complicated project but building my confidence in the DRO and it’s setup.

Not a very complicated project but building my confidence in the DRO and it’s setup.