GummyMonster

Ken

Good day,

I've been wanting to post this for some time, but the website was being very buggy for me. A big thanks to Janger and the other fellows that sorted out the issues.

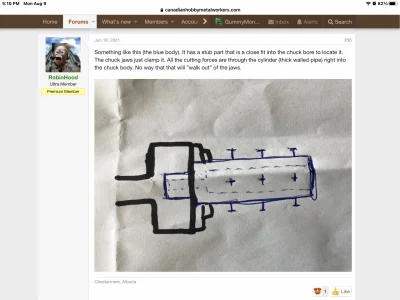

Ok, in the "Dirt Cheap Automatic Tailstock Feed for Your Metal Lathe" thread, Susquatch and RobinHood are discussing double and triple spiders for aligning rifle barrels for boring. I attached a screenshot of one , which I really like the concept of using the chuck bore behind the jaws for stability. I would be using a sleeve behind the jaws and not a solid stub.

My question.

Could this concept be used on a lathe to make it easier to perfectly align the barrel with a chamber reamer. I'm extremely new to all this, but to my thinking, this spider would allow you to adjust for any runout present. You'd have one at the rear of the chuck bore as well. I have a W210 style lathe with a 1 1/2" bore, and I'm really hoping to progress to chambering barrels with it.

Any input is appreciated.

Thanks,

Ken

I've been wanting to post this for some time, but the website was being very buggy for me. A big thanks to Janger and the other fellows that sorted out the issues.

Ok, in the "Dirt Cheap Automatic Tailstock Feed for Your Metal Lathe" thread, Susquatch and RobinHood are discussing double and triple spiders for aligning rifle barrels for boring. I attached a screenshot of one , which I really like the concept of using the chuck bore behind the jaws for stability. I would be using a sleeve behind the jaws and not a solid stub.

My question.

Could this concept be used on a lathe to make it easier to perfectly align the barrel with a chamber reamer. I'm extremely new to all this, but to my thinking, this spider would allow you to adjust for any runout present. You'd have one at the rear of the chuck bore as well. I have a W210 style lathe with a 1 1/2" bore, and I'm really hoping to progress to chambering barrels with it.

Any input is appreciated.

Thanks,

Ken