Richard Tymko

Active Member

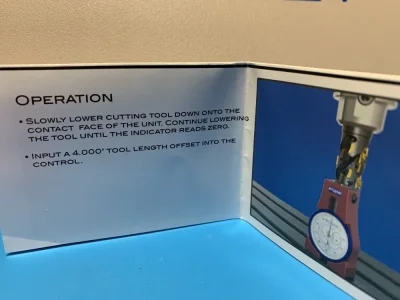

I have an Edge Technology "Pro Touch Off Gauge"

4" tool length offset.

I am offering it up here for a day before I put it on Kijiji. Asking $200.

I bought it over a year ago thinking it would work well with my Pocket NC. Then I upgraded my Pocket NC and never ended up using it.

It is in NEW condition.

4" tool length offset.

I am offering it up here for a day before I put it on Kijiji. Asking $200.

I bought it over a year ago thinking it would work well with my Pocket NC. Then I upgraded my Pocket NC and never ended up using it.

It is in NEW condition.