I've been trying to figure out what the height adjusting screws are on my tool holders.

They are all BXA of various brands and types.

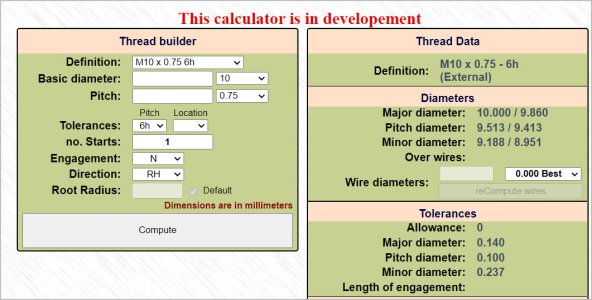

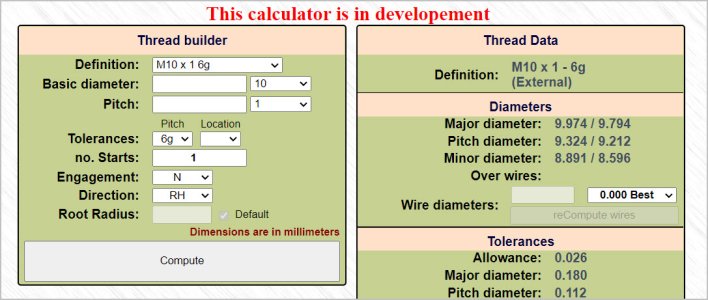

All come with a screw. I always thought it was an M10-1.0. So I bought taps and a die for that.

But they don't seem to fit.

The thread on the screws and holders is almost certainly 1.0 pitch within reasonable measurement. But the diameter is whacky. Almost all of them measure 9.83mm. Not 10. A 10mm stud cut with the 10-1.0 die will not thread into the hole.

If I reduce the diameter and cut it with the die, it still won't go into the hole.

However, if I cut the diameter to 9.8 and then single point thread deeper than spec, they work fine.

Similarly, a hole drilled and tapped to spec is loose as a goose on a factory stud.

Given the number of holders I have and the time between buying my first and my last, I doubt very much that my own experience is unique. I bet most users with BXA toolposts have a similar issue.

Does anyone have any insights on this matter?

They are all BXA of various brands and types.

All come with a screw. I always thought it was an M10-1.0. So I bought taps and a die for that.

But they don't seem to fit.

The thread on the screws and holders is almost certainly 1.0 pitch within reasonable measurement. But the diameter is whacky. Almost all of them measure 9.83mm. Not 10. A 10mm stud cut with the 10-1.0 die will not thread into the hole.

If I reduce the diameter and cut it with the die, it still won't go into the hole.

However, if I cut the diameter to 9.8 and then single point thread deeper than spec, they work fine.

Similarly, a hole drilled and tapped to spec is loose as a goose on a factory stud.

Given the number of holders I have and the time between buying my first and my last, I doubt very much that my own experience is unique. I bet most users with BXA toolposts have a similar issue.

Does anyone have any insights on this matter?