Almost done. But close enough for posting purposes. Looks like they will work. I am not sure about "texturing" for locking the lamp in various positions but I figure if it needs something, I might put a knurl on it or insert rubber gasket/washer/disc. A bit of fit and trial to do tomorrow. Honestly, no need for a mill on this one. I roughed them out on the bandsaw, milled to the traced scribed line (mostly cause I wanted an excuse to use the mill), then finished with a file and sanding disc. Having said that, The mill, being used as a rigid accurate drill press, was good for drilling the hole (concave feature which is a pivot point). I never took a picture but I clamped the two old pieces together, (after gluing them back together to get better dimensions) determined that a 5/16" bit would cut both halves nicely if bolted together, then did as much of it as I could with a 5/16 2 flute end mill. When I ran out of cutter length, I finished with a 5/16 drill bit but at least I had a good guide by then.

I am hoping the brass stands up better than the aluminum as I only got about 8 years out of that.....

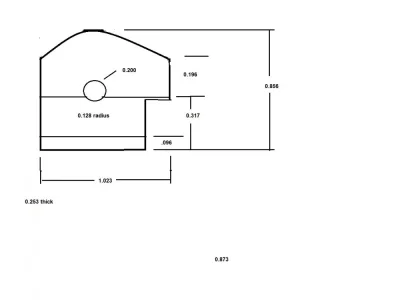

As an aside, I see the CAD thread running. I have wanted to learn CAD for years and started many times but usually/always gave up. Working from drawings like that is really nice to do, but for the stuff I do, a napkin is more efficient. Lately though, I have been sketching stuff up in Paint, even if just to the point where I can write the dimensions on later or in the shop. I find the dimension lines are a pita to do sometimes. The drawing can be fun. So I threw that pic in here as well. Someday, I hope to concentrate on learning a CAD program. I will follow that thread.

Happy Superbowl day! (Not a huge football follower but I like the food associated with the game....)

Cheers,

Shawn