Dan Dubeau

Ultra Member

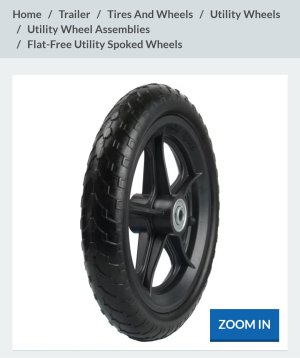

I am. Almost everything I own that rides on cheap rubber/plastic tires is broken. I finally had enough, and decided to do something about it....

First step was to buy some steel, as I didn't have anything suitable on hand. Let me just get this out of the way right now, this is not a financially motivated decision, this is one born out of frustration and a desire to end the hassle of perpetually flat and broken tires everytime I need to move something.....I will do the math at the end, just to see the true cost of these though. I went with 3/16"x2" flat for the rim, and 3/16"x1.5" for the spokes. I bored some 1/2" pipe out a bit to fit the 5/8" axles.

Next step was to send them through the roller. Was really hoping that this duct roller would be up to the task. I've rolled 1/8"x2" before so I was hopeful. It did, but was a work out, and I don't think it was happy...... None of my drills or impacts would spin it, so it was all by hand with a 24" breaker bar. Wasn't really too bad though, and went pretty quick. I think it was 12 trips through the rollers. I guesstimated on having to burn about 4" on each end that I'd have to chop, but that was too much. Next ones I will only leave about 4" total for waste.

Printed some radius gauges onto some cardstock for 8, 10 and 12" wheels.

I cannot get this roller to roll straight. I spend a good deal of time trying to align the rolls, and the steel, etc, but I think there's just too much flex and slop in it from being pushed beyond it's design purpose that it's just something I'll have to deal with. Hopefully I can straighten them out....

I then cut off a bit from one end, and measured the circumference needed. Went with a nice round 31.5" on these instead of 31.4, but should be close enough......

Chopped them to length, and manipulated them in a vise to close them up and align the ends. I used a ratchet strap to close them up for tacking, and a kant twist on the seam for alignment. With some twisting and persuading they lined right up pretty easily.

I tacked up the inside, removed the clamps and strap then welded the inside completely. Then I ran a cutting disc down the outside groove, so I could weld that up with some better penetration.

I also chopped up some hubs, and bored them out while they were cooling. Then ground them all smooth.

Next step is to fill in the blanks......

First step was to buy some steel, as I didn't have anything suitable on hand. Let me just get this out of the way right now, this is not a financially motivated decision, this is one born out of frustration and a desire to end the hassle of perpetually flat and broken tires everytime I need to move something.....I will do the math at the end, just to see the true cost of these though. I went with 3/16"x2" flat for the rim, and 3/16"x1.5" for the spokes. I bored some 1/2" pipe out a bit to fit the 5/8" axles.

Next step was to send them through the roller. Was really hoping that this duct roller would be up to the task. I've rolled 1/8"x2" before so I was hopeful. It did, but was a work out, and I don't think it was happy...... None of my drills or impacts would spin it, so it was all by hand with a 24" breaker bar. Wasn't really too bad though, and went pretty quick. I think it was 12 trips through the rollers. I guesstimated on having to burn about 4" on each end that I'd have to chop, but that was too much. Next ones I will only leave about 4" total for waste.

Printed some radius gauges onto some cardstock for 8, 10 and 12" wheels.

I cannot get this roller to roll straight. I spend a good deal of time trying to align the rolls, and the steel, etc, but I think there's just too much flex and slop in it from being pushed beyond it's design purpose that it's just something I'll have to deal with. Hopefully I can straighten them out....

I then cut off a bit from one end, and measured the circumference needed. Went with a nice round 31.5" on these instead of 31.4, but should be close enough......

Chopped them to length, and manipulated them in a vise to close them up and align the ends. I used a ratchet strap to close them up for tacking, and a kant twist on the seam for alignment. With some twisting and persuading they lined right up pretty easily.

I tacked up the inside, removed the clamps and strap then welded the inside completely. Then I ran a cutting disc down the outside groove, so I could weld that up with some better penetration.

I also chopped up some hubs, and bored them out while they were cooling. Then ground them all smooth.

Next step is to fill in the blanks......