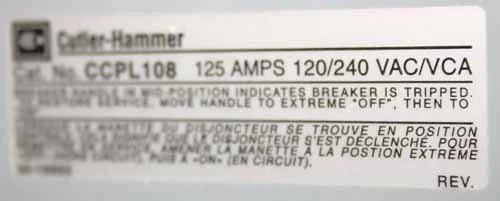

PeterT: It is extremely likely that your in-house panel is labeled incorrectly. One set of 40A breakers is probably for the stove. The other may be for the garage. If you have an electric dryer there will likely be a pair of 30A breakers for that. It would be a very bad thing (both illegal and very unsafe) to parallel two sets of breakers to feed the garage. So, you probably have a 40A 220V service to the garage.

To clear up the whole deal of what happens when you use two breakers to get 220V, you do in fact double the power available. The power is the current times the voltage. So, the power available from a single 15A 120V circuit is about 1800 watts. From a 15A 220V circuit (supplied by two 15A breakers) it is 15A times 240V = 3600W. With a 220V circuit the power comes out from one breaker and returns on the other. So double the power is available.

A standard household service in Canada (and the US in general) is properly called "split-phase power". It consists of two 120V RMS (nominal, sometimes called 110V or 115V) AC lines that are 180 degrees out of phase and one neutral line. Neutral is very similar to ground. The electrical company provides the two hots and a ground to your service entrance. At that point the ground is literally grounded to the ground and from there on the neutral and ground lines continue on as separate things to the breakers and the loads. The neutral should always be very close to ground potential, but can vary slightly when things are under load. The ground line should always be at ground potential. It is there for safety only. Ground lines should never carry current (except when they are doing their safety thing and carrying current to ground because of a wiring problem).

So that leaves you with the neutral (always white), and the two hots (generally black, but sometimes red when dealing with 220V). There is 120V available between either of the hots and neutral and 240V available between the two hots (they are 180 degrees out of phase so they add up to 240V). The breakers are always on the hot lines. That is why there is only one for 120V and two for 240V. Two hots from the same phase are in phase (0 degress out of phase), so they add up to zero voltage between them.

With 120V one line is hot (black), and one neutral (white). The neutral line is very close to ground in potential so it is not really "dangerous". If neutral shorts to ground nothing will really happen in most cases. One hot line varies between ground and +169V. The other varies between ground and -169V. The voltage varies 60 times a second (60Hz). Since the hot lines are 180 degrees out of phase one is high while the other is low so the voltages simply add. When you measure across both hots, it goes from -169V to +169V for a range of 338V total.

Where did 169V come from???? That is the actual peak voltage of the sine wave of the AC voltage. Divide 169 by the square root of 2 (1.414), and you get 120V RMS (Root Mean Square). That is the effective "average" voltage of the line which give you the "average" power that is available. The RMS voltage is what is generally quoted rather than the peak. The peak is always 1.414 times the RMS when the current is a sine wave. This is a simplifications, but it is pretty close to the truth.

Inside the breaker panel: The main bus bars the breakers plug into will alternate between phase-A and Phase-B. A set of breakers placed across two bus bars will have 220V RMS across them. If the two breakers are plugged into the same phase, they will have zero volts across them (there will still be 120V between each breaker's output and neutral). Linking the breakers does not create the 220V, placing the linked breakers across two phases does that. The linking of the breakers is for safety so that if one blows, the other will as well, completely turning off the 220V. Non linked breakers across the two phases will work fine to provide 220V. Note that that does not meet code and is not safe.

There is no problem with oversubscribing within a breaker panel. They are designed for that. When a panel is rated for 60A, it means that the maximum it can be safely fed with is a circuit protected by a 60A breaker (and the appropriate thickness of wire). It is quite normal to have a total of 200A of breakers in a panel rated at 60A and fed by an upstream 60A breaker. If the total current actually drawn by all the circuits in the panel exceeds 60A, it will blow the breaker in the upstream source.

PererT: If your garage is actually fed by a conduit the whole way, it is likely possible to pull thicker wires through from your house panel to your garage panel. Then you could upgrade the house panel to have a 60A breaker, and add a 40A circuit in the garage to feed the hungry 'ol TIG, and still have enough power left over to run the lights and stereo while welding at full power. It is common for the conduit to only go a bit below ground level, then have burial rated wires just buried in the dirt (usually with something like a 2x4 above them for physical protection). In that case, you can't pull new wires through without re-digging the trench.

Did I just completely muddy up the waters, or does what I said actually make sense to anybody???