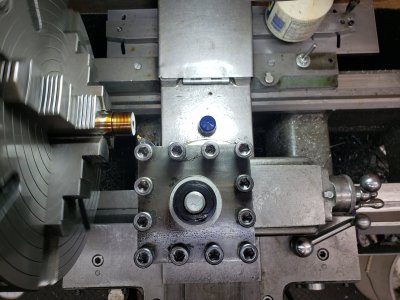

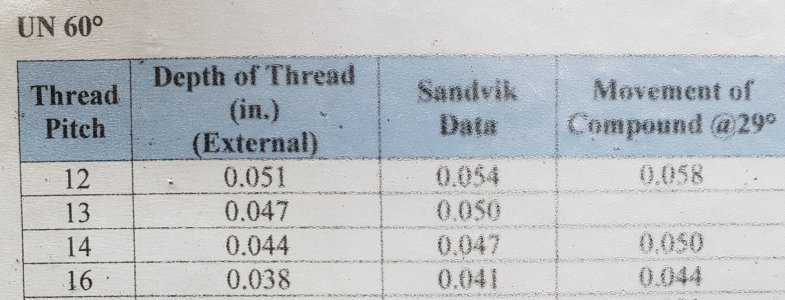

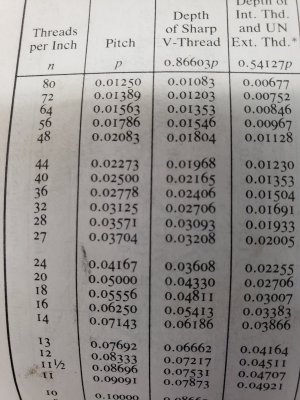

In the beginning....reading everything I could about threading on the lathe, the consensus was to set your compound to 30° or 29°. I've used HSS factory shaped or bits shaped by myself on the grinder, (that usually ended in frustration), lay down carbide inserts, or vertical carbide inserts. Some topping inserts, but mostly non-topping carbide inserts. And over the years I have found this method which suits me best. Setting the compound to move in the axial direction (parallel to the ways). Depth of cut controlled by the cross-slide, therefore a radial indeed. Using Sandvik Top-Lok holders and non-topping inserts. Once I've made a number of passes to reach the desired depth of cut for that thread pitch according to the Sandvik tables, I'll try to screw in the corresponding nut/part. If it is too tight, I will move the compound slide back 0.001" to clean up the back side of the thread, then test. If it still does not fit, I start moving the compound forward towards the chuck in 0.001" increments and testing every time, until the nut/part screws on without binding or excessive play. In this way I can achieve the desired pitch diameter, with the minimum depth. Sometimes threading thin walled items you might need as much wall thickness as possible. If I was using a sharp hss bit, I would need to go 0.054" deep to get the proper pitch diameter (16tpi), but I only went in 0.041" radially and 0.010" axially to get the same pitch diameter. 0.013" is not much on solids bar stock, but can be marginal on thin walled items. The topping lay down inserts would achieve this too, except you need a different one for every different pitch.

Attachments

-

20220226_120200.jpg434.4 KB · Views: 22

20220226_120200.jpg434.4 KB · Views: 22 -

20220226_140937.jpg278.8 KB · Views: 20

20220226_140937.jpg278.8 KB · Views: 20 -

20220226_123628.jpg363.1 KB · Views: 20

20220226_123628.jpg363.1 KB · Views: 20 -

20220226_123638.jpg310.5 KB · Views: 21

20220226_123638.jpg310.5 KB · Views: 21 -

20220226_123702.jpg522.1 KB · Views: 19

20220226_123702.jpg522.1 KB · Views: 19 -

20220226_130000.jpg631.8 KB · Views: 16

20220226_130000.jpg631.8 KB · Views: 16 -

20220226_131607.jpg332.8 KB · Views: 17

20220226_131607.jpg332.8 KB · Views: 17 -

20220226_134504.jpg329.5 KB · Views: 20

20220226_134504.jpg329.5 KB · Views: 20