Since the very beginning of my machining experience on a lathe, I have always done 29.5 degree threading. I thought everyone did it this way. But I recently learned from @gerritv that while this practice is mostly common in North America, the rest of the world normally cuts their threads using a 90 degree plunge cut. Apparently the rest of the world handles the increased chip load by reducing the depth of cut as the threading tool is advanced.

This global difference bothers me so much that I have created this new thread to discuss it with my fellow members.

The idea behind the 30 degree cut is to cut on just one face of the 60 degree tool and slide along the other. Cutting on only one face reduces the chip load on the tool by half. Sometimes this leaves a rough chattered surface on the sliding edge. Rarely, it can even leave a bit of a staircase effect. The idea behind the 29.5 degree cut is to cut the normal 30 degree plus a little 1/2 degree shave off of the other surface to clean it up and eliminate the possibility of any staircasing. I have no idea how the 1/2 degree was decided. I do know that it is not critical.

When plunge cutting at 90 degrees, this 1/2 degree difference is not needed because both edges cut all the time. As stated above, the increased cutting load from cutting on both edges is reduced by gradually reducing the depth of cut as the tool is advanced in order to maintain a constant chip/cutting load. I also think it's rather obvious to me that chip loading is not a concern for small fine threads.

At first, I accepted the global difference as just another example of common practice differences. Perhaps even like metric VS imperial.

But I slept on the matter last night and I came to realize that there is another potential difference that "might" be important. And it further occurred to me that there may be other factors at play that I have never considered or perhaps never even heard of.

Most of us don't have tool room grade or cnc lathes. Many of us have old lathes that are well worn. Some of us have low cost machines that were never intended for high precision use. One of the most common wear items is the leade screws. We learn early on to accommodate leade screw backlash by loading the leade screw in one direction only. Essentially, this keeps the tooling indexed against the pressure/loaded side of the leade screw which greatly reduces the effect of any backlash.

In a plunge cut, the vast majority of the load is radial and there is very little side loading of the leade screws. Most of the tool locating forces are generated by the tool profile - essentially the tool mostly follows the groove.

On the other hand cutting on the side of a tool creates higher side loads which should increase the load on the leade screws and thereby ensure that there is no backlash affecting the path of the tool.

Basically, I am suggesting that another reason for cutting a thread on just one face of the tool (the 30/29.5 practice) might be to improve the geometric precision of the thread by using the cutting forces to reduce the backlash effect. I realize that much of the backlash is taken up purely by the sideways movement of the tool. But I also think this isn't as reliable or as consistent as higher side loading might provide.

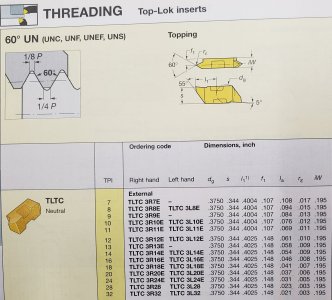

For me, perhaps the most compelling argument to the contrary is the Sandvik recommendations wherein they provide a chart of tool advancement settings for each thread settings for cutting at 90 degrees. This clearly supports the practice of plunge cut threading at 90 degrees. But perhaps their recommendations are for professional use with cnc machines or tool room lathes - not potentially well-worn sloppy hobbiest lathes.

I am hoping that some of the other members here have more experience and knowledge on the matter than I do and can help sift through the pros and cons of 30/29.5 degree threading VS 90 degree plunge cut threading. Is it really just a matter of choice or are there compelling reasons why we should prefer one method over the other?

What do you folks think?

This global difference bothers me so much that I have created this new thread to discuss it with my fellow members.

The idea behind the 30 degree cut is to cut on just one face of the 60 degree tool and slide along the other. Cutting on only one face reduces the chip load on the tool by half. Sometimes this leaves a rough chattered surface on the sliding edge. Rarely, it can even leave a bit of a staircase effect. The idea behind the 29.5 degree cut is to cut the normal 30 degree plus a little 1/2 degree shave off of the other surface to clean it up and eliminate the possibility of any staircasing. I have no idea how the 1/2 degree was decided. I do know that it is not critical.

When plunge cutting at 90 degrees, this 1/2 degree difference is not needed because both edges cut all the time. As stated above, the increased cutting load from cutting on both edges is reduced by gradually reducing the depth of cut as the tool is advanced in order to maintain a constant chip/cutting load. I also think it's rather obvious to me that chip loading is not a concern for small fine threads.

At first, I accepted the global difference as just another example of common practice differences. Perhaps even like metric VS imperial.

But I slept on the matter last night and I came to realize that there is another potential difference that "might" be important. And it further occurred to me that there may be other factors at play that I have never considered or perhaps never even heard of.

Most of us don't have tool room grade or cnc lathes. Many of us have old lathes that are well worn. Some of us have low cost machines that were never intended for high precision use. One of the most common wear items is the leade screws. We learn early on to accommodate leade screw backlash by loading the leade screw in one direction only. Essentially, this keeps the tooling indexed against the pressure/loaded side of the leade screw which greatly reduces the effect of any backlash.

In a plunge cut, the vast majority of the load is radial and there is very little side loading of the leade screws. Most of the tool locating forces are generated by the tool profile - essentially the tool mostly follows the groove.

On the other hand cutting on the side of a tool creates higher side loads which should increase the load on the leade screws and thereby ensure that there is no backlash affecting the path of the tool.

Basically, I am suggesting that another reason for cutting a thread on just one face of the tool (the 30/29.5 practice) might be to improve the geometric precision of the thread by using the cutting forces to reduce the backlash effect. I realize that much of the backlash is taken up purely by the sideways movement of the tool. But I also think this isn't as reliable or as consistent as higher side loading might provide.

For me, perhaps the most compelling argument to the contrary is the Sandvik recommendations wherein they provide a chart of tool advancement settings for each thread settings for cutting at 90 degrees. This clearly supports the practice of plunge cut threading at 90 degrees. But perhaps their recommendations are for professional use with cnc machines or tool room lathes - not potentially well-worn sloppy hobbiest lathes.

I am hoping that some of the other members here have more experience and knowledge on the matter than I do and can help sift through the pros and cons of 30/29.5 degree threading VS 90 degree plunge cut threading. Is it really just a matter of choice or are there compelling reasons why we should prefer one method over the other?

What do you folks think?