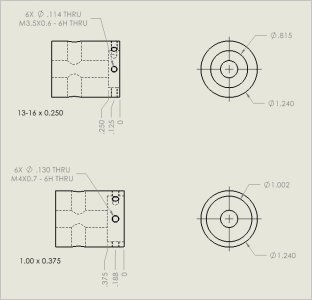

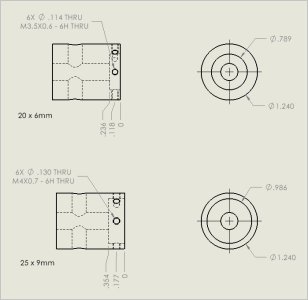

I decided to make some die heads for threading on the lathe. I don't get along well with they typical handle wrenches. They can be fussy to align to stock using tailstock quill or whatever. I also don't like wrenching, its easy to distort the part especially the small stuff. The issue with dies is they come in so many dimensional standards. Different OD, metric, imperial, different thickness, different retention dimple orientation, adjustable, non-adjustable (which affects OD). I initially tried to standardize on TMX 13/16" & 1" OD which covers most of the small stuff range. I was getting them from KBC which was under their house label. But I started noticing they were slipping other stuff here & there, some of it so-so & again, slightly different. I also recently tried a few non-adjustable metric dies in some smaller pitches. The quality varies by supplier but I think they are OK. TMX is a good brand IMO but they only come in adjustable.

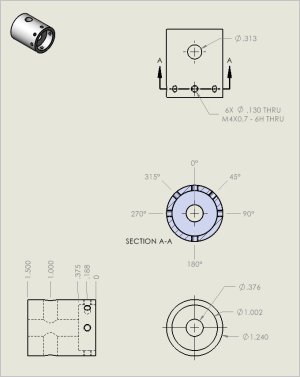

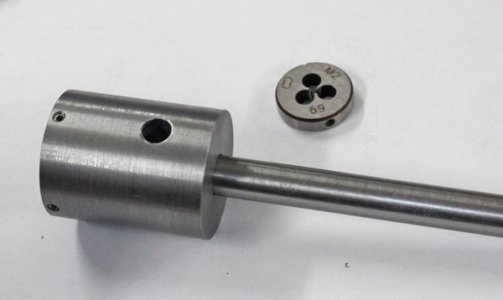

So I tried to come up with a standard cup with same set screw pattern, slider shaft bore & just make the die recess to suite the (5 and counting) styles I have. What I learned is you need to provide sufficient cup ID to accommodate the expansion based on thread fit. For example I was making them 1.00" ID because the nominal OD is 1", but eventually I found its better to be 2-3 thou over. Not a big deal but now its not quite on center. So I made 4 opposed set screws to give it some 4-jaw effect & 2 extra top ones at 45-deg which seems to correspond to others.

So I tried to come up with a standard cup with same set screw pattern, slider shaft bore & just make the die recess to suite the (5 and counting) styles I have. What I learned is you need to provide sufficient cup ID to accommodate the expansion based on thread fit. For example I was making them 1.00" ID because the nominal OD is 1", but eventually I found its better to be 2-3 thou over. Not a big deal but now its not quite on center. So I made 4 opposed set screws to give it some 4-jaw effect & 2 extra top ones at 45-deg which seems to correspond to others.