I was fortunate enough to pick up this tool post grinder, its a CJ40 it has the 3 spindles small grind wheel, large grind wheel and 6.43mm chuck, we spun it up briefly and it sounded a bit sluggish but we were out in a shed but $150 later it was mine I gave it a quick start at home it seemed better so maybe their power was poor but I want to give everything a good going over and proper lubrication before running it up for any length of time. Looks like they are still able to supply parts if I need anything. I am pretty stoked I think it has a lot of potential and I am close to finishing one project so this one will move into the queue this winter. From what I can see it looks pretty complete just need some grinding wheels a bit of hardware and and a few pulleys for speed changes.

chuck, we spun it up briefly and it sounded a bit sluggish but we were out in a shed but $150 later it was mine I gave it a quick start at home it seemed better so maybe their power was poor but I want to give everything a good going over and proper lubrication before running it up for any length of time. Looks like they are still able to supply parts if I need anything. I am pretty stoked I think it has a lot of potential and I am close to finishing one project so this one will move into the queue this winter. From what I can see it looks pretty complete just need some grinding wheels a bit of hardware and and a few pulleys for speed changes.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Themac tool post grinder

- Thread starter combustable herbage

- Start date

That's a great price even of you have to piecemeal parts. I hope the bearings in the spindle cartridge are in good shape, that's the heart of the machine & where the $$ occurs.

Themac is still around & so is the J40 model. I've spoken to them a few times. You may not like the price of new parts though. If you disassemble, try & get familiar beforehand with what's involved regarding bearings, resetting, oil....

You can mount TPG on top of the compound as its usually done. Probably the biggest reason/advantage is you can set the compound to a shallow angle & therefore your net in-feed is much finer increment. Hint compound angle set at 5.7 deg yields a tenth (0.0001") infeed for each 0.001" line increment of compound. (But remember diameter reduction is 2 x 0.0001" so 0.0002").

Or if you have T slots on the rear of your sliding table, you can mount there. This isn't done as often but may offer advantages as the compound assembly can contribute to finish/accuracy issues depending on the lathe. In this regard the Themac design is versatile in that the spindle cartridge can rotate up/down the circular tee slots to different vertical positions.

Themac is still around & so is the J40 model. I've spoken to them a few times. You may not like the price of new parts though. If you disassemble, try & get familiar beforehand with what's involved regarding bearings, resetting, oil....

You can mount TPG on top of the compound as its usually done. Probably the biggest reason/advantage is you can set the compound to a shallow angle & therefore your net in-feed is much finer increment. Hint compound angle set at 5.7 deg yields a tenth (0.0001") infeed for each 0.001" line increment of compound. (But remember diameter reduction is 2 x 0.0001" so 0.0002").

Or if you have T slots on the rear of your sliding table, you can mount there. This isn't done as often but may offer advantages as the compound assembly can contribute to finish/accuracy issues depending on the lathe. In this regard the Themac design is versatile in that the spindle cartridge can rotate up/down the circular tee slots to different vertical positions.

Well Craig this really sucks more, the thing is basically bolt on there is an opening and the bolt has holes to use a pin to tighten with a nut that will have to be machined to hold it in, the unit is really balanced especially on the compound. When I went there she had it in the shed cause it had power and it was advertised with 2 spindles, so she asked if I wanted to look at the other stuff it was an auction lot and I had looked at the other items online and there wasn't anything I was really interested in but I went for a look and she saw the other spindle and threw it in and then I bought some air cylinders but I was really glad I went for a look cause we found that spindle. So I will have to mill a new nut for it and now I will be able to as I purchased a king pdm-30 today and I am picking it up in 10 days.

more, the thing is basically bolt on there is an opening and the bolt has holes to use a pin to tighten with a nut that will have to be machined to hold it in, the unit is really balanced especially on the compound. When I went there she had it in the shed cause it had power and it was advertised with 2 spindles, so she asked if I wanted to look at the other stuff it was an auction lot and I had looked at the other items online and there wasn't anything I was really interested in but I went for a look and she saw the other spindle and threw it in and then I bought some air cylinders but I was really glad I went for a look cause we found that spindle. So I will have to mill a new nut for it and now I will be able to as I purchased a king pdm-30 today and I am picking it up in 10 days.

Pic-1: The conventional mounting arrangement presumes a T plate in the compound very similar to typical tool post plate. It has a threaded hole to match the clamping part you show with the radial holes. Yes you use a tommy bar rod to tighten. But looks like your cross slide does not have this T plate feature, so will require a workaround.

Pic-2: my idea to table mount the TPG by making adapter plate with same motor housing bolt pattern & then fasten plate to table T-slots.

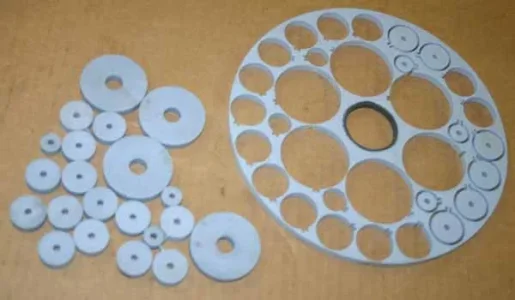

Pic-3: water cut stones from 1/4" surface grinder wheel.

Pic 4,5: portable dressing tool fixture

Pic-2: my idea to table mount the TPG by making adapter plate with same motor housing bolt pattern & then fasten plate to table T-slots.

Pic-3: water cut stones from 1/4" surface grinder wheel.

Pic 4,5: portable dressing tool fixture