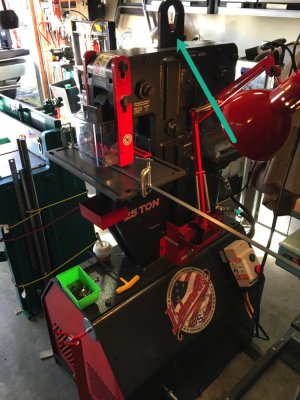

The pics of straps is fortunate, indicating proceed with purchase caution. Even if it 'only' bent the lowermost hex rod (which is the power on/off/forward/reverse) that is relatively easy replacement. But depending on how the straps were placed & threaded, the associated Gronk force is also imparted to the apron which is attached. If the straps were ever directly or even indirectly around the upper lead screw & power feed bars, I would bet its a heavy basket of trouble. It could easily bow tension to the lead screw, power feed rod & impart force to all the close tolerances associated parts behind the apron, like worm gear mechanism or half-nut mechanism if lever happened to be closed. If that picture wasn't taken & you just walked up to the lathe, how would you ever know what it was subjected to behind the scenes? I guess the moral with used is run the lathe & operate the feeds unless you are a gambler type & like this sort of challenge.

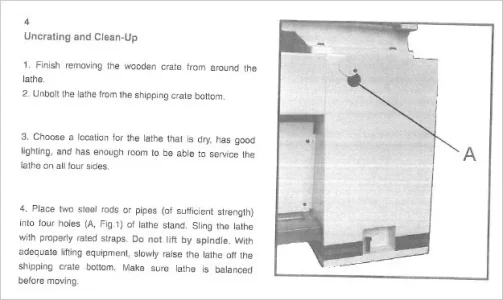

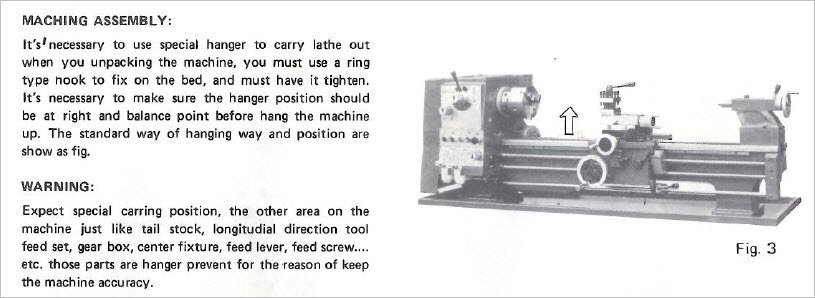

The Modern 14x40 (my dream machine) has dedicated holes through the body for inserting lifting rods. That keeps straps & chains off the delicate, expensive parts.