I've told some of you I was taking the plunge on this bad boy. I've toasted several 12" disk sanders in the past that were designed primarily for wood working. So I applied Donald Trump's Immigration Policy (GET OUT!) to several items in my shop and freed up the space for a machine I have always wanted. After some glitches with Modern Tool (all minor communications-related), I finally received "The Beast" today.

The fellow who delivered it was phenomenal -- I've never seen anyone so skilled on a crane in my life. Most guys who have delivered stuff in the past had it swinging like a kite in the wind. But this guy knew his equipment and was gentle as could be. Great service. Based on him I immediately forgave the communications issues with Modern altogether. He was great. For the record, most of my issues were actually with Kalamazoo in Minnesota who couldn't seem to deliver to schedule.

Technically my machine is the lowest powered one they make. It's only 1.5 HP (220V 1PH). But for me this is SO much better than the 1/3 HP Crappy Tire 12" and Busty Bee ones I used to own. The Kalamazoo DS20 model weighs in at 550 lbs (but I think this is overstated). What I do know is the bearings in the Baldor motor are great. Once shut down, it takes 27-30 mins to come to a full stop. Wow. That's a bulky disk and awesome momentum. It wasn't clear on the website for Kalamazoo, but it appears there may be a brake kit available. Once I recover from toxic tax and shipping shock, I may investigate this. This thing was !@#$ expensive, so I may have to sell members of my family to pay for it. Watch the Classified Section of this forum if you need a strong male teenager with a questionable work ethic...(great hair though).

The first PSA disk I tried came from Amazon, and shredded instantly (see sad pic). Initially I thought it was because it was paper-backed for wood, but it turned out it was in fact cloth-backed. After some research and examining the PSA backing, I noticed that it was significantly less tacky than the single courtesy disk that came from Kalamazoo. Their included disk worked fine, and was much more tacky. I have heard that PSA has a shelf life and can deteriorate over time. One tip I read is after pressing on the machine you should use a heat gun to make the PSA more tacky, then re-set the disk--especially if you suspect the PSA is old. I will try this next time. I have ordered some standard aluminum oxide disks from Sandpaper Family Inc. in Ontario. They haven't arrived yet. But if they work well, I will stick a crowbar in may wallet and try the blue Zirconia versions, and post results.

What I Like About This Machine:

- USA/North American Made (and BOY do they remind you of this when you pay for it). The exception is the internationally sourced "reclaimed" iron, which I am fine with.

- Baldor motor (love these). I have an older 3/4 HP Baldor buffer that I love as well. Expensive, but good resale value.

- Adjustable table - functional and aids in PSA replacement.

- Square D reversing switch.

- Hefty, bulky, beefy cast base, properly machined table, hardened gears, robust adjustment wheels, locking hubs, solid rack and pinion lifting mechanism for the table, and industry endorsed electrics.

- Discharge chute for dust. I will add a collection cup in the future.

- Pivoting Guard - also aids in PSA replacement.

- Clearly QA/QC'd by manufacturer (the machine, not the manual and safety labels--see below). Machine blue marks still visible on disk...looks like it was vibration tested as well. Centre indicators for table angle were within 1 degree of run-out straight out of the crate.

- Pretty quiet by my standards: 61.2 dBs as measured on a DrMeter in front of machine as an operator (after starter kicks out).

Minor Things I Dislike:

- The electrics online are misleading as they show both a reversing switch AND a ON/OFF button. I would have preferred this. The ON/OFF function on my version is controlled from the reversing switch with a central OFF position. I think is a cheap way to do it. Why? Because the working switch lever is the only plastic part on the whole machine, and a clear fail point. Either the switch with its central OFF position should be metal, or it needs the older version that uses a reversing switch w/ the push button ON/OFF. Additionally, from a safety perspective, the red OFF button is nearing a "universal standard" that most of us can relate to, and react to, in an emergency. I will try it as is for now, but may retrofit a ON/OFF button in the future. Realistically "emergency" OFF with a machine like this is a misnomer: with almost a half hour's worth of momentum in the disk, the concept of shut down is more about saving on your power bill than your fingers.

- The manual sucks, and it's only a couple of pages! That's impressive if underachievement is your corporate vision, but not so great if you're a customer. OK, I was a technical writer for years when I was younger so I am biased. Most manuals suck. But, as just one fecal-rotting example...there are two Zerks on the motor, but no instruction or maintenance schedule associated with them.

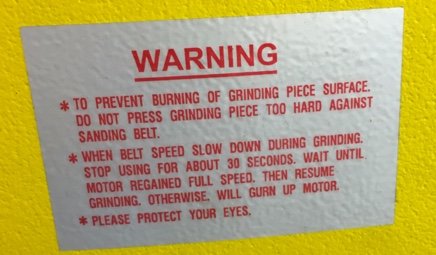

- I get nervous when instructions and safety stickers are written by functional illiterates, engineers or lawyers who don't care to check the spelling, grammar, or readability of text that the government requires us to legally adhere to (see pics). After paying a premium for a North American product, I expect better English that what I am accustomed to on Asian machines, or at least something better than a sticker that's been proof-read by Huell from Better Call Saul. Jeeze Loweeze.

Sound petty? The issue here is that--if they don't take the time to check the safety labels they put on the darn machine and the English instructions they write in the manual--did they actually care about taking the time to check the wiring? What about the tolerances? Shouldn't someone, somewhere, in charge of promoting a better quality "MADE IN USA" product worry about this?

So....Kalamazoo (and other USA companies who wish to instil confidence in perspective customers because you build locally):

- Center your text on Safety Labels so you don't have to hyphenate it. For example: (GLASSES WHEN OPERAT-

ING THIS MACHINE!)

- Check your subject-verb agreement: (WHEN BELT SPEED SLOW DOWN DURING GRINDING.)

- Write in complete sentences: (TO PREVENT BURNING OF GRINDING PIECE SURFACE.) (WAIT UNTIL MOTOR REGAINED FULL SPEED.) (THEN RESUME GRINDING.) (OTHERWISE WILL GURD UP MOTOR.)

Not sure what "GURD" is, but it sounds bad....really bad. I think cats do this when their stomach is upset. No wait...I think I heard about this on Jerry Springer.

- Still investigating, but it does not appear that the table distance from disk is easily adjustable. The safety issue here is that you should never grind stock that is smaller than the gap between the disk and the table. When you are using courser grits such as 50 vs a 300, there is a significant gap between your disk and the table. You don't want stock entering that gap. Or gloves. Or fingers. Or other body parts. (Best not to allow your imagination wander here). UPDATE: After some poking around this is adjustable via the motor mount. Turns out there are dedicated slots for just this purpose...not on the motor itself, but where the mount bracket attaches to the cast stand.

Improvements:

- I will look at the option of retrofitting a brake, making one, or adding a amber strobe light (maybe driven by an Arduino base timer), that alerts me to the spinning of the disk 30 mins post shut down. Overly-geeky I know...but cheeper and more fun than a brake. Maybe...we'll see. Mechanical petals...brake pads...manly smells they emit...all cool...we'll see.

- A mounting bracket for the included mitre gauge when not in use. Will need a spring loaded holder to prevent vibration noise.

- A dust container for slag, dust, etc., on the discharge chute (Note to Gardeners: mix the steel slag/dust with water and feed to your evergreens...they love the iron!)

- A water coolant container so I won't be tempted to operate with gloves on...which I often do .

.

Summary:

So all-in-all, I like the Kalamazoo DS20. I have tested it on 3/16 and 1/4 square tubing and it does what I wanted. Granted I am only one day into testing, but so far I like what I see.

The fellow who delivered it was phenomenal -- I've never seen anyone so skilled on a crane in my life. Most guys who have delivered stuff in the past had it swinging like a kite in the wind. But this guy knew his equipment and was gentle as could be. Great service. Based on him I immediately forgave the communications issues with Modern altogether. He was great. For the record, most of my issues were actually with Kalamazoo in Minnesota who couldn't seem to deliver to schedule.

Technically my machine is the lowest powered one they make. It's only 1.5 HP (220V 1PH). But for me this is SO much better than the 1/3 HP Crappy Tire 12" and Busty Bee ones I used to own. The Kalamazoo DS20 model weighs in at 550 lbs (but I think this is overstated). What I do know is the bearings in the Baldor motor are great. Once shut down, it takes 27-30 mins to come to a full stop. Wow. That's a bulky disk and awesome momentum. It wasn't clear on the website for Kalamazoo, but it appears there may be a brake kit available. Once I recover from toxic tax and shipping shock, I may investigate this. This thing was !@#$ expensive, so I may have to sell members of my family to pay for it. Watch the Classified Section of this forum if you need a strong male teenager with a questionable work ethic...(great hair though).

The first PSA disk I tried came from Amazon, and shredded instantly (see sad pic). Initially I thought it was because it was paper-backed for wood, but it turned out it was in fact cloth-backed. After some research and examining the PSA backing, I noticed that it was significantly less tacky than the single courtesy disk that came from Kalamazoo. Their included disk worked fine, and was much more tacky. I have heard that PSA has a shelf life and can deteriorate over time. One tip I read is after pressing on the machine you should use a heat gun to make the PSA more tacky, then re-set the disk--especially if you suspect the PSA is old. I will try this next time. I have ordered some standard aluminum oxide disks from Sandpaper Family Inc. in Ontario. They haven't arrived yet. But if they work well, I will stick a crowbar in may wallet and try the blue Zirconia versions, and post results.

What I Like About This Machine:

- USA/North American Made (and BOY do they remind you of this when you pay for it). The exception is the internationally sourced "reclaimed" iron, which I am fine with.

- Baldor motor (love these). I have an older 3/4 HP Baldor buffer that I love as well. Expensive, but good resale value.

- Adjustable table - functional and aids in PSA replacement.

- Square D reversing switch.

- Hefty, bulky, beefy cast base, properly machined table, hardened gears, robust adjustment wheels, locking hubs, solid rack and pinion lifting mechanism for the table, and industry endorsed electrics.

- Discharge chute for dust. I will add a collection cup in the future.

- Pivoting Guard - also aids in PSA replacement.

- Clearly QA/QC'd by manufacturer (the machine, not the manual and safety labels--see below). Machine blue marks still visible on disk...looks like it was vibration tested as well. Centre indicators for table angle were within 1 degree of run-out straight out of the crate.

- Pretty quiet by my standards: 61.2 dBs as measured on a DrMeter in front of machine as an operator (after starter kicks out).

Minor Things I Dislike:

- The electrics online are misleading as they show both a reversing switch AND a ON/OFF button. I would have preferred this. The ON/OFF function on my version is controlled from the reversing switch with a central OFF position. I think is a cheap way to do it. Why? Because the working switch lever is the only plastic part on the whole machine, and a clear fail point. Either the switch with its central OFF position should be metal, or it needs the older version that uses a reversing switch w/ the push button ON/OFF. Additionally, from a safety perspective, the red OFF button is nearing a "universal standard" that most of us can relate to, and react to, in an emergency. I will try it as is for now, but may retrofit a ON/OFF button in the future. Realistically "emergency" OFF with a machine like this is a misnomer: with almost a half hour's worth of momentum in the disk, the concept of shut down is more about saving on your power bill than your fingers.

- The manual sucks, and it's only a couple of pages! That's impressive if underachievement is your corporate vision, but not so great if you're a customer. OK, I was a technical writer for years when I was younger so I am biased. Most manuals suck. But, as just one fecal-rotting example...there are two Zerks on the motor, but no instruction or maintenance schedule associated with them.

- I get nervous when instructions and safety stickers are written by functional illiterates, engineers or lawyers who don't care to check the spelling, grammar, or readability of text that the government requires us to legally adhere to (see pics). After paying a premium for a North American product, I expect better English that what I am accustomed to on Asian machines, or at least something better than a sticker that's been proof-read by Huell from Better Call Saul. Jeeze Loweeze.

Sound petty? The issue here is that--if they don't take the time to check the safety labels they put on the darn machine and the English instructions they write in the manual--did they actually care about taking the time to check the wiring? What about the tolerances? Shouldn't someone, somewhere, in charge of promoting a better quality "MADE IN USA" product worry about this?

So....Kalamazoo (and other USA companies who wish to instil confidence in perspective customers because you build locally):

- Center your text on Safety Labels so you don't have to hyphenate it. For example: (GLASSES WHEN OPERAT-

ING THIS MACHINE!)

- Check your subject-verb agreement: (WHEN BELT SPEED SLOW DOWN DURING GRINDING.)

- Write in complete sentences: (TO PREVENT BURNING OF GRINDING PIECE SURFACE.) (WAIT UNTIL MOTOR REGAINED FULL SPEED.) (THEN RESUME GRINDING.) (OTHERWISE WILL GURD UP MOTOR.)

Not sure what "GURD" is, but it sounds bad....really bad. I think cats do this when their stomach is upset. No wait...I think I heard about this on Jerry Springer.

- Still investigating, but it does not appear that the table distance from disk is easily adjustable. The safety issue here is that you should never grind stock that is smaller than the gap between the disk and the table. When you are using courser grits such as 50 vs a 300, there is a significant gap between your disk and the table. You don't want stock entering that gap. Or gloves. Or fingers. Or other body parts. (Best not to allow your imagination wander here). UPDATE: After some poking around this is adjustable via the motor mount. Turns out there are dedicated slots for just this purpose...not on the motor itself, but where the mount bracket attaches to the cast stand.

Improvements:

- I will look at the option of retrofitting a brake, making one, or adding a amber strobe light (maybe driven by an Arduino base timer), that alerts me to the spinning of the disk 30 mins post shut down. Overly-geeky I know...but cheeper and more fun than a brake. Maybe...we'll see. Mechanical petals...brake pads...manly smells they emit...all cool...we'll see.

- A mounting bracket for the included mitre gauge when not in use. Will need a spring loaded holder to prevent vibration noise.

- A dust container for slag, dust, etc., on the discharge chute (Note to Gardeners: mix the steel slag/dust with water and feed to your evergreens...they love the iron!)

- A water coolant container so I won't be tempted to operate with gloves on...which I often do

Summary:

So all-in-all, I like the Kalamazoo DS20. I have tested it on 3/16 and 1/4 square tubing and it does what I wanted. Granted I am only one day into testing, but so far I like what I see.

Attachments

Last edited: