DPittman

Ultra Member

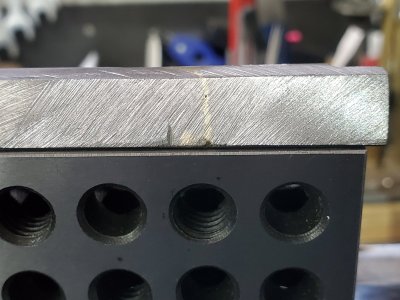

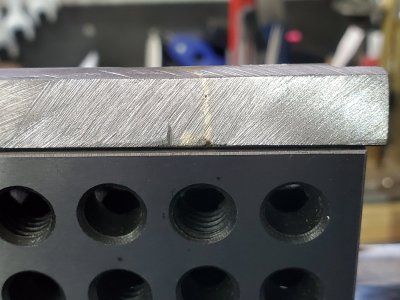

I'm needing a tapered gib for the compound slide on an old 12x36 king/enco lathe and of course part number is obsolete and manufacturer doesn't list it any more.

I'm guessing it is the same on many other lathes. Any one with a modern Asian 12×36 lathe want to take a look and see if the dimensions in my photo look like my gib might work in your lathe? My hope is that I can then order with a modern part number.

I'm guessing it is the same on many other lathes. Any one with a modern Asian 12×36 lathe want to take a look and see if the dimensions in my photo look like my gib might work in your lathe? My hope is that I can then order with a modern part number.