I recently finished up a taper turning attachment for my Standard Modern 16" Utilathe. And it works!! I utilized several different designs which I Googled. Most of the material was from stuff laying around the shop, which means, cold rolled, hot rolled, O1, A2, aluminium.

Attachments

-

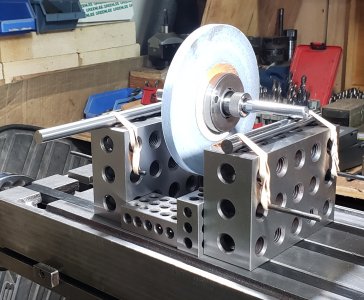

Grinding Wheel Balancer #2.jpg484.7 KB · Views: 62

Grinding Wheel Balancer #2.jpg484.7 KB · Views: 62 -

Grinding Wheel Balancer.jpg312.2 KB · Views: 59

Grinding Wheel Balancer.jpg312.2 KB · Views: 59 -

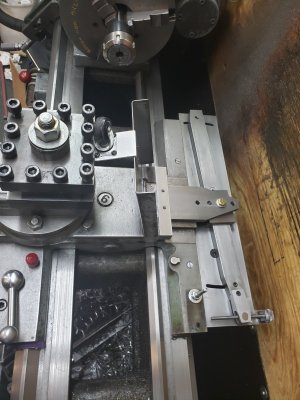

Spindle Taper Wipers.jpg423.2 KB · Views: 62

Spindle Taper Wipers.jpg423.2 KB · Views: 62 -

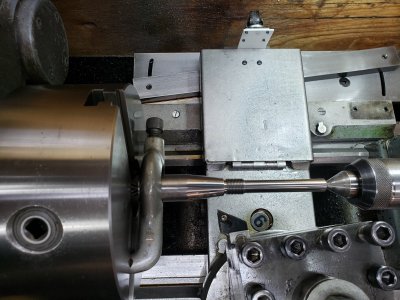

Taper Turning Attachment #1.jpg500.4 KB · Views: 67

Taper Turning Attachment #1.jpg500.4 KB · Views: 67 -

Taper Turning Attachment #2.jpg421.9 KB · Views: 66

Taper Turning Attachment #2.jpg421.9 KB · Views: 66 -

Taper Turning Attachment #3.jpg384.4 KB · Views: 66

Taper Turning Attachment #3.jpg384.4 KB · Views: 66