Matt_b_m

Member

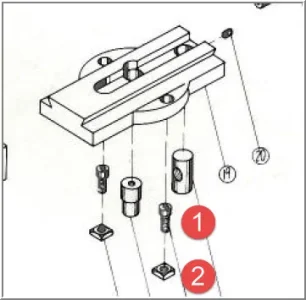

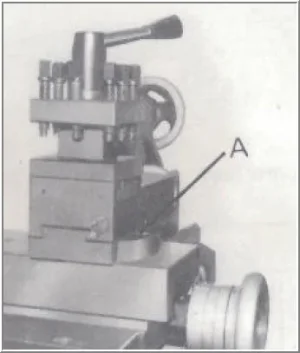

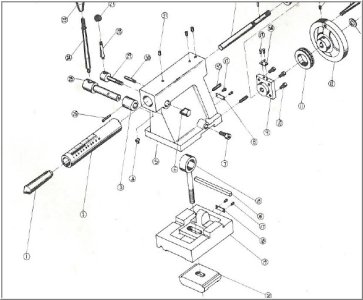

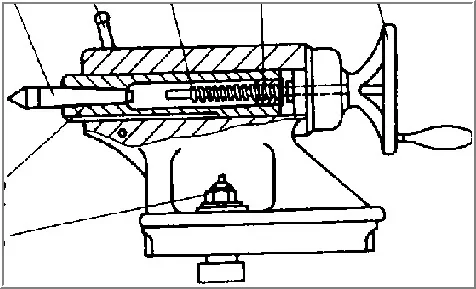

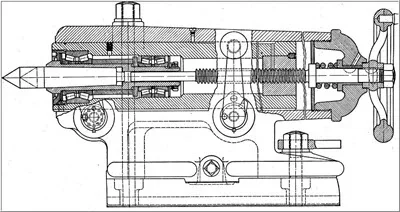

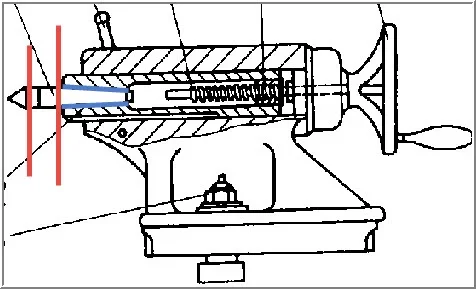

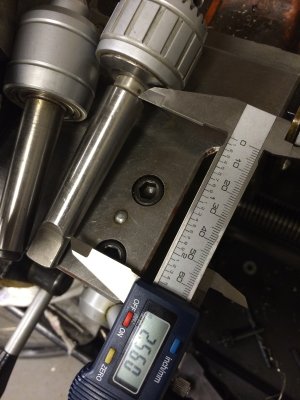

Just took a few moments over lunch to begin to dissemble and clean the new to me Tida-4A lathe i picked up yesterday. Taking my time I removed the tailstock, set it aside and started wiping down the rest. I took a moment to remove the tool post and noticed that the bolts in the compound looked shall I say "too shiny" and out of place. A closer look and it is obvious these along with their washers were added at some point in its life and appear to be hand carved (file, grinder) with matching washers with flat sides as well. I've found the parts diagram for the lathe online, but it doesn't reveal anything more than there is in fact two bolts in this location.

I know finding replacement original parts is essentially a unicorn hunt, but I'm wondering if any of you have had to replace these T bolts and nuts before on any of your equipment, and where you may have found a selection. I am unsure of the original length, but its obviously a part that as long as its long enough, its long enough to work.

As always, any help is appreciated.

Thanks.

I know finding replacement original parts is essentially a unicorn hunt, but I'm wondering if any of you have had to replace these T bolts and nuts before on any of your equipment, and where you may have found a selection. I am unsure of the original length, but its obviously a part that as long as its long enough, its long enough to work.

As always, any help is appreciated.

Thanks.