I'm working on forging a custom skillet with a fancy handle. So far I've done it all over the anvil, but it is difficult to get the sides perfectly curved and the bottom perfectly flat without a mold or a swage block.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Swage blocks.

- Thread starter Chris Cramer

- Start date

Bofobo

M,Mizera(BOFOBO)

And making a swage block is not easy. That’s where I was at in my smithing adventure when I bought machines to make accessories, I finally found (aka free for a popper) piece of metal big enough to make one. But I’m starting with pritchel hole accessories first. Some pretty interesting guillotine style tools have been made to emulate a power hammer with interchangeable dies for features but damned if I can find one to show.

Yeah, I don't know any better way than to cast a swage blog either with aluminum or steel. I do have a 14" wide 1" thick plate of steel that I'm planning on cutting with a hand held plasma torch into a cone like ring that will give me the shape I need to forge a clean skillet.

What about making a swage block by milling out the shape in thick metal with a CNC - or even with a rotary table and manually. Rough with big end mills then finish with ball end mill? maybe further refine with right angle die grinder and sanding wheels then roloc wheels? Then heat treat ?

Could you even stack the 1" stock you have Chris into a double pile? Bolt together and then mill? If you don't have a suitable mill I can give you a hand.

Could you even stack the 1" stock you have Chris into a double pile? Bolt together and then mill? If you don't have a suitable mill I can give you a hand.

I don't have a mill, and my goal is to build a 12" swage block. I just got 9 1/2 inch 4"x8" plates of steel from work. so I could weld those into 2 12 inch squares and stack them on top of the 1inch stock I have to make up 12"x 2" stock.

I don't think the 12 inch plates would warp after butt welding the 4x8x1/2 inch plates together; but I don't think my forge could get hot enough to forge weld those stacked plates together into a solid block.I wonder if they would warp if you welded a stack together. That's why I thought maybe bolting plates together would work.

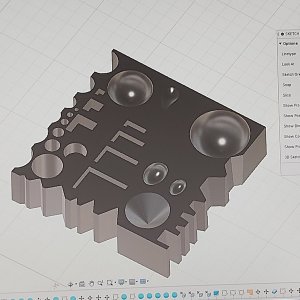

Those blocks are only 1" thick and only contain common holes that are cut through the entire block. That could easily be cut with my plasma table, but I'm looking for a block with some domes, and more shapes than open circles and squares. I finished designing a block on fusion 360, I just need to find the stock for it.

Can you post an image of your Fusion design please.... I'm not following what it is you are trying to make.Those blocks are only 1" thick and only contain common holes that are cut through the entire block. That could easily be cut with my plasma table, but I'm looking for a block with some domes, and more shapes than open circles and squares. I finished designing a block on fusion 360, I just need to find the stock for it.

Those blocks are only 1" thick and only contain common holes that are cut through the entire block. That could easily be cut with my plasma table, but I'm looking for a block with some domes, and more shapes than open circles and squares. I finished designing a block on fusion 360, I just need to find the stock for it.

Can you grind a concave shape in a large stump?

I could probably grind a large concave shape out of a stump with my die grinder. That would definitely take a while, and it would probably be fairly difficult to get the shape very even by hand.

Bofobo

M,Mizera(BOFOBO)

Are you trying to get uniform domed accents on flat? My understanding is the through hole allows the forming hammer to press from behind into the opening creating a uniform dome, unlike a large steel stamping in a die one and done, pounding more than once may distort the effect, just a thought though

I could probably grind a large concave shape out of a stump with my die grinder. That would definitely take a while, and it would probably be fairly difficult to get the shape very even by hand.

Might not be too bad if you were able rough out the shape with a grinder and then level a jig or guide on the stump and use a router to produce a uniform cavity.

So far I shaped the concave skillet over a round die, but that still leaves several uneven areas. A 12" hole would allow me to shape those with a rounding hammer. However an even concave dapping block gives me something to follow and makes it much easier to hammer down a more smooth even dome.Are you trying to get uniform domed accents on flat? My understanding is the through hole allows the forming hammer to press from behind into the opening creating a uniform dome, unlike a large steel stamping in a die one and done, pounding more than once may distort the effect, just a thought though

the skillet I have now could possibly be made even by grinding, because it is 3/16" thick which is a bit too heavy.

Here is the design of what I have in mind. the large bowl on one side is what I would use to shape a uniform skillet, all the other bowls could be used for rounding certain metal stock. I also decided to add some more custom shapes that I would use, like a spoon, and a wrought iron leaf.

Attachments

I was debating if I should just do it out of cement. A more simple design could be done that way like if I only included the main cavity and the outside swages.Some of the old time presses were done with cement forms.