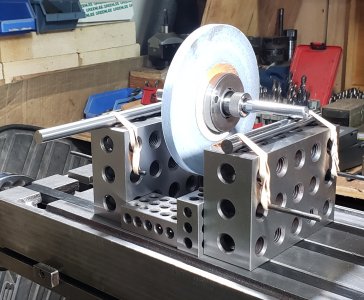

I made a balancing ring for my adapter a couple years ago. I only had one grinding wheel, so I only made one.

Well, I have another wheel now, and probably another one or two in the future. So I decided to make a few more rings.

Well, I have another wheel now, and probably another one or two in the future. So I decided to make a few more rings.