DPittman

Ultra Member

I thought I would start a new thread to glean some ideas to help me avoid some mistakes I'm likely to make with out some input from those that know stuff that I don't.

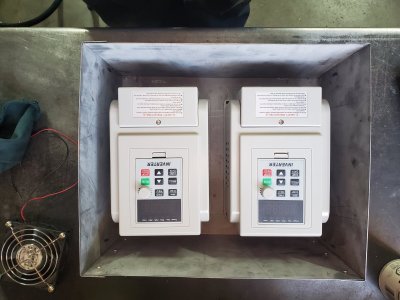

My plan is to mount two recently purchased vfd's in one protective box on the wall and then remotely mount the control panels on the machines themselves.

One vfd will control a milling machine and one will control a drill press. I thought about using one vfd for two machines but the vfds were so cheap I chose to use separate vfds for each machine.

I think I will have a master switch between power source (220v) and the vfd's. I am then undecided whether I need another switch on the machine or if the vfd panel stop/run button is enough for each machine.

I am wondering if it would be ok to run power line to the first vfd and then just wire the power over to the next one beside it? I won't ever be running the two machines at the same time.

My milling machine already has a forward/reverse switch on it....that gets removed right because the vfd has that built in?

My plan is to mount two recently purchased vfd's in one protective box on the wall and then remotely mount the control panels on the machines themselves.

One vfd will control a milling machine and one will control a drill press. I thought about using one vfd for two machines but the vfds were so cheap I chose to use separate vfds for each machine.

I think I will have a master switch between power source (220v) and the vfd's. I am then undecided whether I need another switch on the machine or if the vfd panel stop/run button is enough for each machine.

I am wondering if it would be ok to run power line to the first vfd and then just wire the power over to the next one beside it? I won't ever be running the two machines at the same time.

My milling machine already has a forward/reverse switch on it....that gets removed right because the vfd has that built in?