I purchased the PM-835TV Mill below, but didn't buy the matching stand since I thought a custom stand would suit me better.

This is what I'm thinking of for my design constraints (in order of priority):

1) Must allow full Z travel, ideally when a future ceiling is installed (about 50mm required for a T-bar ceiling, though I could just use 5/8" drywall in the vicinity of the Mill).

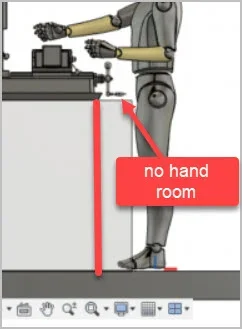

2) The height of the stand should be maximized, but not so high that controls are uncomfortable to reach.

3) Width about the same as the travel of the table.

4) Depth so that I don't hit myself on the Y handle.

Optional:

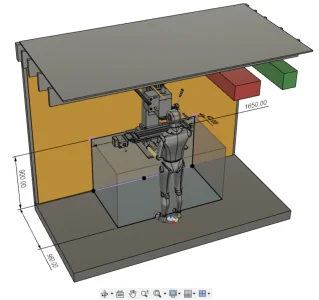

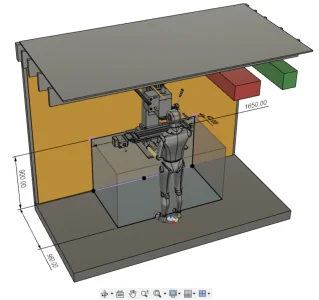

O1) It would be nice if the stand is low enough so that it can be moved under the "Red" HVAC duct and "Green" wooden beam with the mill installed on the stand (see images below).

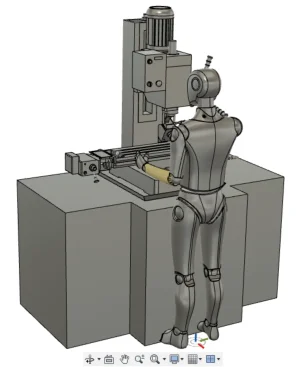

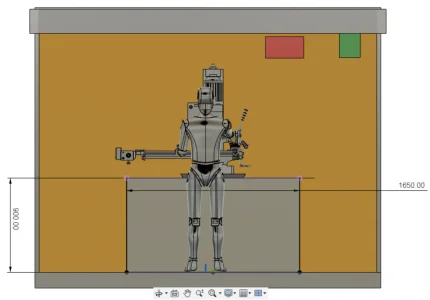

This is the general concept, it's what I call a "massing model", it shows the overall dimensions but not any of the detail:

The purpose of the front "notches" is so that I can reach around the Mill easier, to operate the Z-axis power feed.

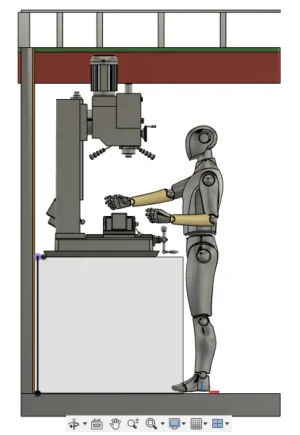

Here you can see the "Red" HVAC duct and the "Green" beam:

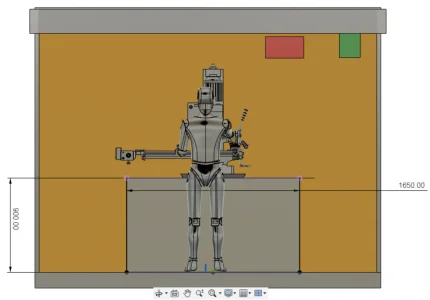

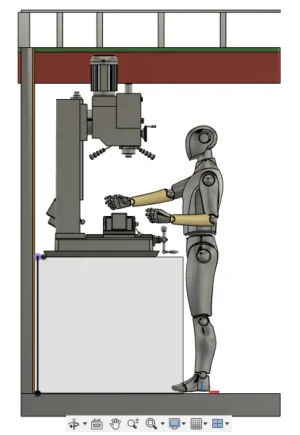

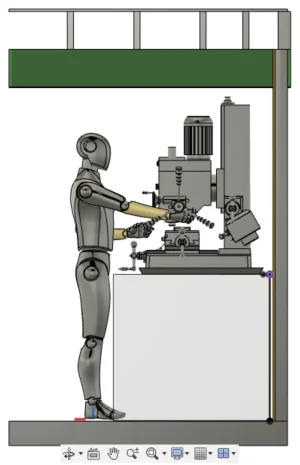

Front view with the table moved all the way to the left, the power feed just overhangs the end of the table:

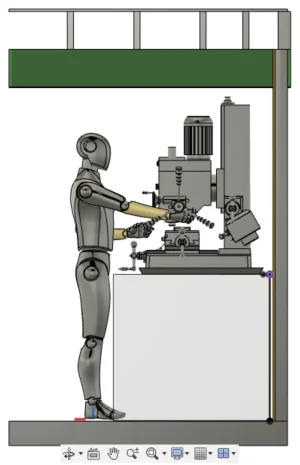

In the left view, the head raised to the full height leaves about 50mm from the underside of the beams:

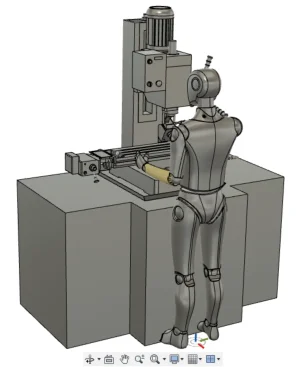

In the right view, with the head lowered down the top of the Mill will fit under the "Green" beam:

(The Human Model is about 20mm shorter than I am, so that's why it's not sitting quite on the floor slab)

(I made the model for the Mill in Fusion 360. It doesn't include all details, though since I like modelling I made it more complicated than it needs to be...)

(The PM-835TV weighs about 750lbs (340kg), so I think the stand will ultimately end up being quite substantial. About the only thing that is potentially set in stone is that I've got some 2"x2"x1/4" thick tubing for the cross members)

This is what I'm thinking of for my design constraints (in order of priority):

1) Must allow full Z travel, ideally when a future ceiling is installed (about 50mm required for a T-bar ceiling, though I could just use 5/8" drywall in the vicinity of the Mill).

2) The height of the stand should be maximized, but not so high that controls are uncomfortable to reach.

3) Width about the same as the travel of the table.

4) Depth so that I don't hit myself on the Y handle.

Optional:

O1) It would be nice if the stand is low enough so that it can be moved under the "Red" HVAC duct and "Green" wooden beam with the mill installed on the stand (see images below).

This is the general concept, it's what I call a "massing model", it shows the overall dimensions but not any of the detail:

The purpose of the front "notches" is so that I can reach around the Mill easier, to operate the Z-axis power feed.

Here you can see the "Red" HVAC duct and the "Green" beam:

Front view with the table moved all the way to the left, the power feed just overhangs the end of the table:

In the left view, the head raised to the full height leaves about 50mm from the underside of the beams:

In the right view, with the head lowered down the top of the Mill will fit under the "Green" beam:

(The Human Model is about 20mm shorter than I am, so that's why it's not sitting quite on the floor slab)

(I made the model for the Mill in Fusion 360. It doesn't include all details, though since I like modelling I made it more complicated than it needs to be...)

(The PM-835TV weighs about 750lbs (340kg), so I think the stand will ultimately end up being quite substantial. About the only thing that is potentially set in stone is that I've got some 2"x2"x1/4" thick tubing for the cross members)