Hi - I purchased a bag of 10, 1" Stainless steel 304 balls which I intend to use for various handles and knobs on some machines.

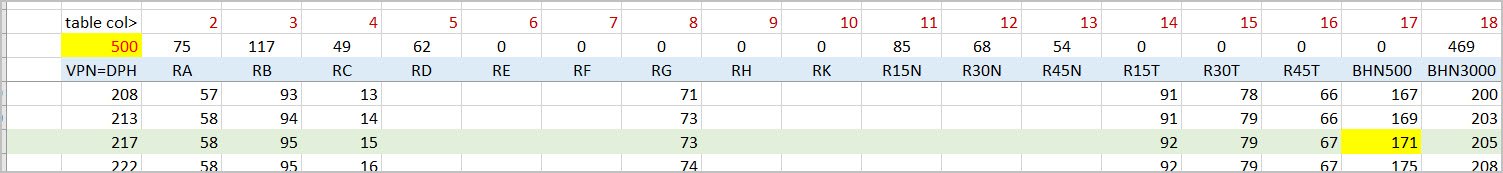

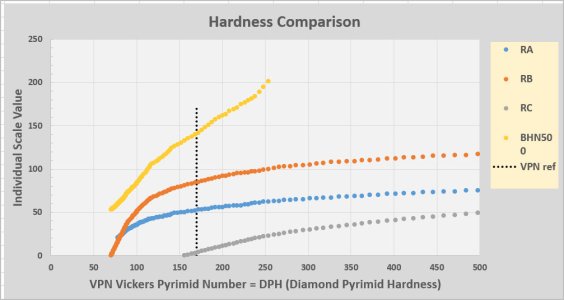

The (Amazon) product info says Hardness HRC <25 which is a bit odd because SS 304 should be harder than that.

Since these will be drilled and tapped, soft is good. My question though, is the hardening process (available to home machinists) for this material. I have a heat treating oven on the way, good for about 1750F with long programmable soak ramps which should cover all the options.

I am very familiar with heat treatment and hardening of tool steels, but no useful experience with SS. Normally I would consider case-hardening (carburising) because SS 304 is austenitic but again I have no experience with this.

Any thoughts on how to surface or body harden these balls to a consistent quality around RC 50-55 ??

Don Gibson

The (Amazon) product info says Hardness HRC <25 which is a bit odd because SS 304 should be harder than that.

Since these will be drilled and tapped, soft is good. My question though, is the hardening process (available to home machinists) for this material. I have a heat treating oven on the way, good for about 1750F with long programmable soak ramps which should cover all the options.

I am very familiar with heat treatment and hardening of tool steels, but no useful experience with SS. Normally I would consider case-hardening (carburising) because SS 304 is austenitic but again I have no experience with this.

Any thoughts on how to surface or body harden these balls to a consistent quality around RC 50-55 ??

Don Gibson