Most of my threading is typically under 2" in length. I usually have to cut to a shoulder, so lathe speed is around 50rpm so I can disengage the half nuts and back out before hitting the shoulder.

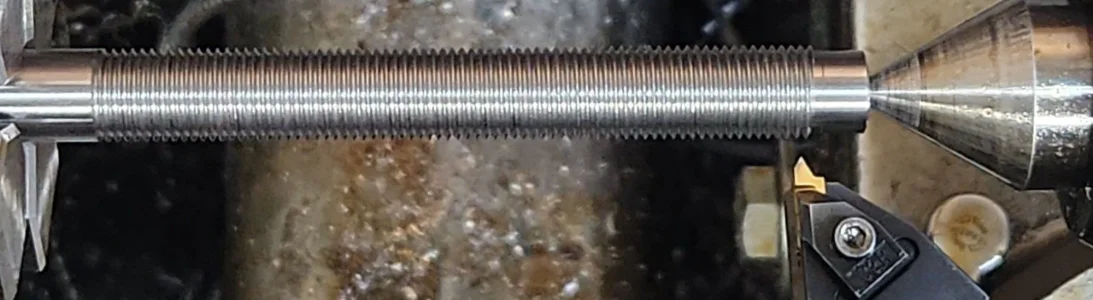

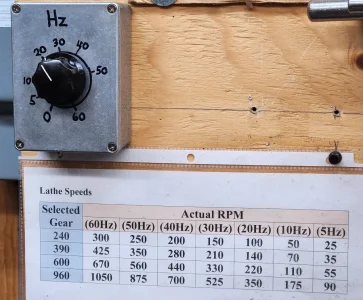

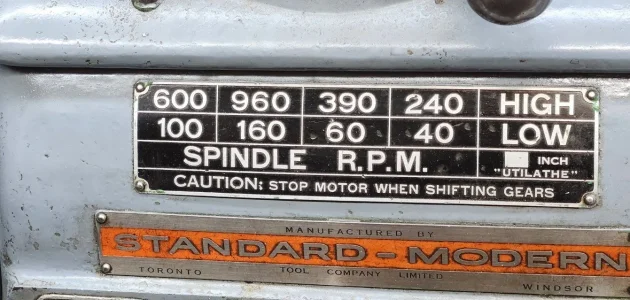

Today I had to make a 1/2"-20 threaded shaft. The threaded portion is 4" long. At 50 rpm, I would have fallen asleep by the time it reached the end. Fortunately, I have a VFD which I've hooked up a potentiometer to control the spindle speed. So I set the pot to 10Hz (50rpm) to start the thread, then increased it to 60hz (300rpm), and then back to 10Hz about 1/2" before the end of the thread to disengage the half-nuts.

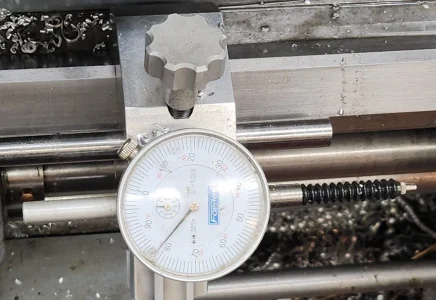

In this case, no shoulder, but I used the carriage indicator to disengage at zero.

Today I had to make a 1/2"-20 threaded shaft. The threaded portion is 4" long. At 50 rpm, I would have fallen asleep by the time it reached the end. Fortunately, I have a VFD which I've hooked up a potentiometer to control the spindle speed. So I set the pot to 10Hz (50rpm) to start the thread, then increased it to 60hz (300rpm), and then back to 10Hz about 1/2" before the end of the thread to disengage the half-nuts.

In this case, no shoulder, but I used the carriage indicator to disengage at zero.