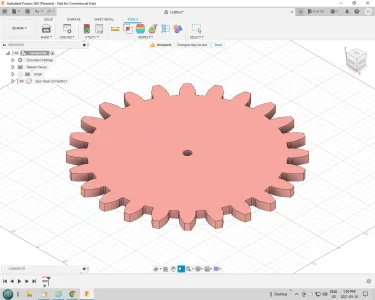

Just ran across these folks on the South Bend Facebook forum. Apparently they make metric transposing gears for the South Bend 9 as well as 'silent' gears for South Bend 13.

https://www.thegearmaker.com/gear-making/

Not cheap...

"Right now, they are $384.95. Not sure if we will be able to keep them at that price point in the future. They are in our web store and on eBay. Feel free to email directly"

https://www.thegearmaker.com/gear-making/

Not cheap...

"Right now, they are $384.95. Not sure if we will be able to keep them at that price point in the future. They are in our web store and on eBay. Feel free to email directly"

Last edited: